Heavy-duty vehicles

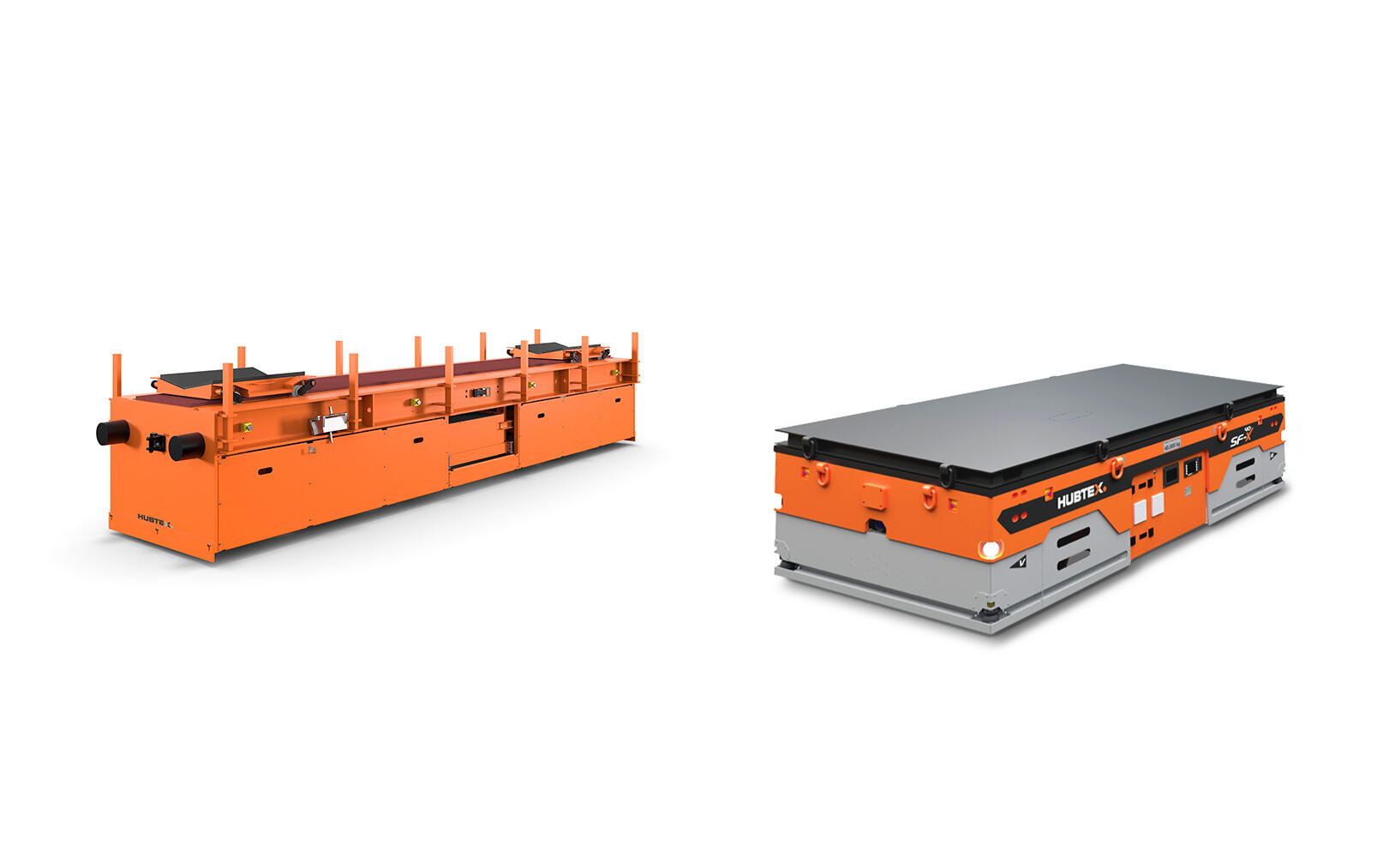

Heavy-duty vehicles are an essential tool for in-plant transportation of heavy and bulky loads in various industries and fields of application. HUBTEX is a leading manufacturer of heavy-duty vehicles. The wide range of different heavy-duty vehicles is designed for transporting loads weighing up to 350 tons. In particular, platform transporters, rail-mounted trucks, tool changers and electric towing tractors play a major role in heavy-duty transport in intralogistics.

Our vehicles are durable and robust. They withstand the toughest operating conditions. HUBTEX heavy-duty vehicles also boast comparatively compact dimensions and high maneuverability. Even working in the tightest of spaces is not a problem.

Which is the best heavy-duty vehicle for your application?

Heavy-duty transport vehicles for almost every application

Das sagen unsere Kunden und Partner

über unsere Produkte und Dienstleistungen.

Discover the advantages for your area of application

Let our product experts help you to find the right heavy-duty vehicle for your application.

Things worth knowing about heavy-duty vehicles

Our answers to your questions

Are there coil transporters, platform trucks and rail cars available as AGVs?

The transport of coils is one of the typical tasks for manufacturers of metal strips and wire in intralogistics. Typically, platform and track wagons are often used for this purpose. Alternatively, HUBTEX offers special coil transporters or electric traction heads as well as heavy duty compact forklifts. These vehicle types form the basis for automated processes. HUBTEX relies on a modular construction kit with automated functions, assistance systems and safety components that are gradually being integrated into series production vehicles. This includes, for example, automatic positioning which navigates the operator directly in front of the correct shelf compartment after entering the desired position. HUBTEX has already anticipated the step-by-step automation with assistance systems: In the basic construction of the vehicles, cable routes, holders and sensors are pre-planned, with which the devices can also be automated later on.