Skip and container

transport

Wastewater treatment plants, waste incineration plants and waste disposal plants rely primarily on skips and containers as load carriers in their logistics. For economical overall processes, these quickly reach a weight of over 22,000 lbs, which can no longer be handled efficiently with standard lift trucks. HUBTEX has developed its own skip and container transporters with a load capacity of up to 55,000 lbs especially for this area of application. Depending on requirements, they come with either an electric drive, diesel or gas drive. The HUBTEX container and skip transporters can be individually adapted to different container sizes.

Individual container sizes:

Depending on the requirement, different load handling variants are available.

TASK AREAS

Skip transporter (CT)

The HUBTEX skip/container transporter is available with two different load handling options, chain slung or swivel arms.

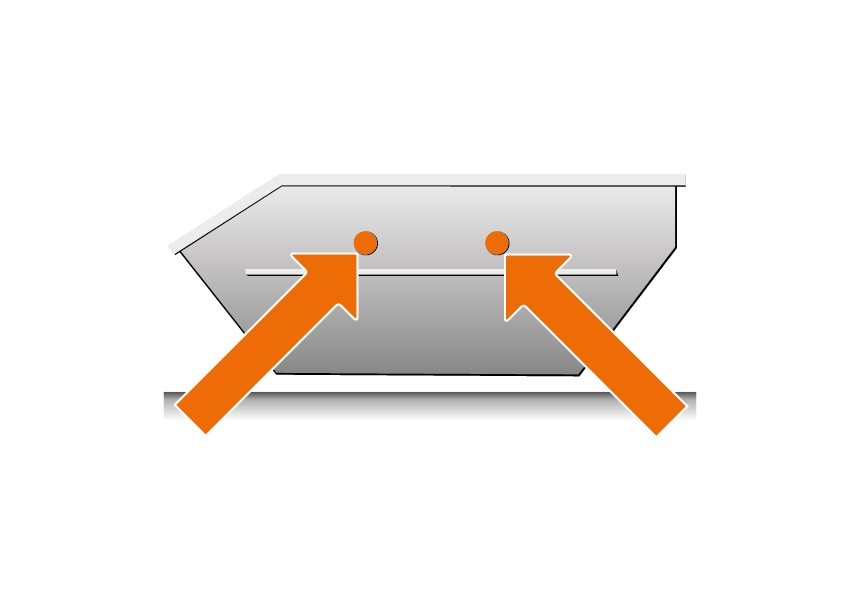

In the version with swivel arms, the truck straddles the skip, the swivel arms extend hydraulically and lift without the driver leaving the cab.

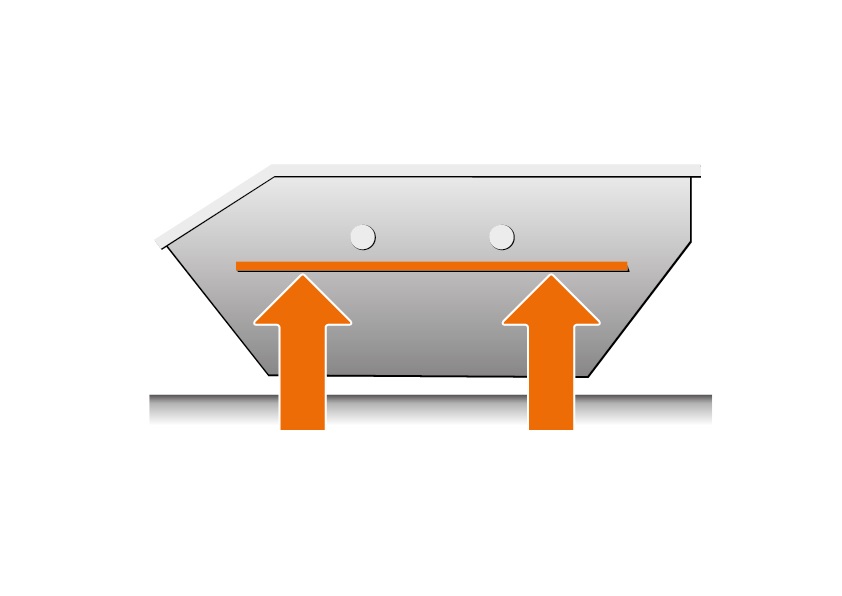

When lifting the loads with conventional chains, the truck straddles the skip, the lifting gear is hitched manually on both sides and the load is then lifted.

Heavy-duty transport systems

Our customers have very diverse wishes and requirements when it comes to transport processes for their containers and skips. Our heavy-duty transport systems, such as the platform truck and the rail-mounted truck, can also be used to transport particularly heavy containers or skips. The surface of the platform or rail-mounted truck is designed depending on the load to be transported – both flat designs and recessed versions with holding rods for containers are possible.

We know the best solution.

We know that handling heavy loads in confined spaces presents users with special challenges. Arrange a non-binding consultation appointment with our specialists to obtain the best possible solution for your application.

CASE STUDIES

What our customers and partners say about our products and services.

Siemens Mobility

Siemens Mobility uses a radio-controlled HUBTEX multi-directional work platform (EPL 03) at its Krefeld plant to pick up, transport, and precisely install side windows in double-decker trains at different heights. The focus was on a mobile alternative to stationary glass handling stations, enabling ergonomic, reliable installation on the upper deck as well. Inductive guidance, multi-directional steering, and vacuum handling support a repeatable, consistent process.

Mubea

Mubea uses the electric HUBTEX SFX 40 platform transporter in its press shop to reliably move press tools weighing up to 40 tons across the plant in three-shift operation. As part of the centralization of tool maintenance, the company needed a solution that combines heavy-duty performance with flexible routing and fast availability. Radio remote control and multi-directional steering enable precise positioning and excellent maneuverability in day-to-day plant traffic.

Volkswagen

Volkswagen in Wolfsburg will rely on the HUBTEX SFX 65 going forward to safely and space efficiently transport press tools weighing up to 65 tons and coils weighing up to 32 tons within the press shop. The company was looking for a flexible alternative to rail guided systems, with all direction mobility, featuring both a flat load deck and a recessed coil pocket. HUBTEX delivered a customer specific version based on the standard vehicle platform.