Coil Handling & Transport Solutions

Looking for reliable steel coil handling equipment? HUBTEX designs electric coil handling forklifts, steel coil material handling equipment such as platform transporters and AGVs, and coil loading equipment for safe, space-efficient moves in mills and service centers. Whether you handle vertical- or horizontal-eye coils, we tailor vehicles to your load, aisle width, and process, from compact multidirectional forklifts to heavy-duty coil transporters.

Task areas

Coil Handling Forklifts

The HUBTEX RoxX combines high capacity with a small turning radius for safe, efficient moves of steel, aluminum, or copper coils. Lower energy/maintenance than diesel, ideal for indoor use and yard transfers. Electric coil handling forklift for tight spaces and heavy loads.

Steel Coil Material Handling Equipment

The HUBTEX Heavy-duty platform transporters form the backbone of steel coil material handling equipment. Low decks, customizable beds, and AGV options enable safe, repeatable coil moves between storage and processing, scalable for long routes and high volumes.

Electric towing tractor with gooseneck

Reliable coil loading equipment for docks and trailer moves. The HUBTEX Electric towing tractor with hydraulic gooseneck couples fast to coil trailers, standardizing transfers and protecting coil edges with smooth acceleration and controlled braking.

The electric multidirectional sideloader from HUBTEX

Boost space utilization in narrow aisles with electric multidirectional trucks, an agile part of our steel coil handling equipment. Multidirectional travel reduces correction moves and supports precise positioning for coils on cradles, racks, or carriers.

Heavy-Duty Electric Multidirectional Sideloaders for Steel Coil Handling

Our heavy-duty electric multidirectional sideloader is a versatile cornerstone of steel coil handling equipment. It safely moves very heavy or bulky coil variants in narrow aisles and open areas, indoors and outdoors. Multidirectional travel shortens approach times and protects product quality, while modular options tailor the truck to your coil dimensions, cradles, floor conditions, and processes, making it a flexible part of your steel coil material handling equipment portfolio.

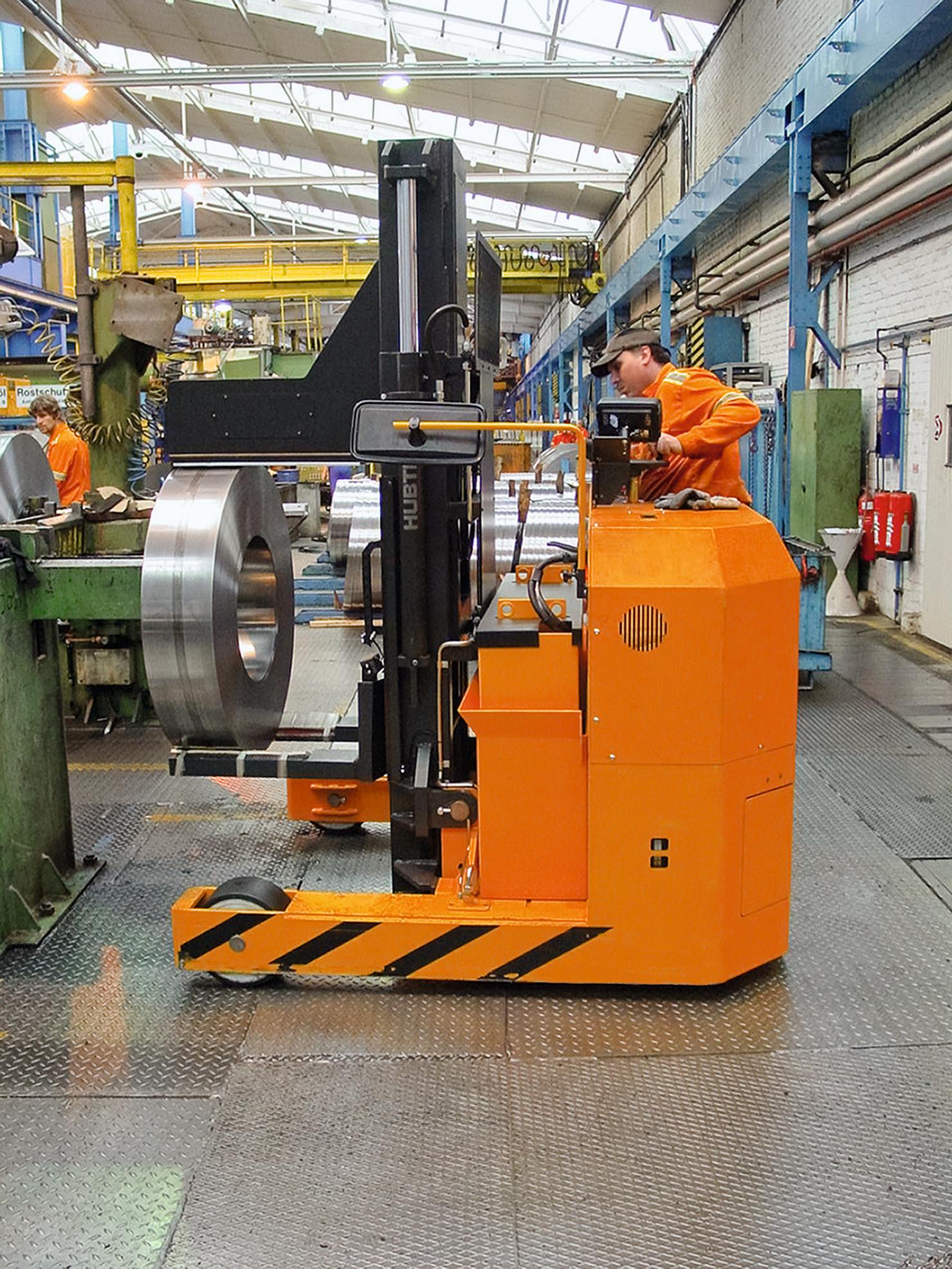

Coil Transporters for Steel or Copper Coil Handling

The HUBTEX coil transporter is the specialist when it comes to the internal handling of coils for feeding production machines and conveyor systems. Due to its very compact design, this vehicle can also be used with minimal space requirements. The coil transporters are configured individually for each customer.

Reach Trucks for Coil Handling

The HUBTEX NexX reach truck combines a compact footprint with high load capacity up to 13,200 lbs, making it ideal for narrow aisles comparable to conventional reach trucks. As part of our steel coil handling equipment, it enables stable, precise coil moves on cradles or carriers. The energy-efficient control system extends battery run time, while robust mast and chassis design support repeatable, damage-free handling in space-constrained storage and staging areas.

Not sure which Equipment fits your coils?

Talk to a HUBTEX specialist about coil forklifts, transporters, and AGV options tailored to your plant.

CASE STUDIES

What our customers and partners say about our products and services.

Siemens Mobility

Siemens Mobility uses a radio-controlled HUBTEX multi-directional work platform (EPL 03) at its Krefeld plant to pick up, transport, and precisely install side windows in double-decker trains at different heights. The focus was on a mobile alternative to stationary glass handling stations, enabling ergonomic, reliable installation on the upper deck as well. Inductive guidance, multi-directional steering, and vacuum handling support a repeatable, consistent process.

Mubea

Mubea uses the electric HUBTEX SFX 40 platform transporter in its press shop to reliably move press tools weighing up to 40 tons across the plant in three-shift operation. As part of the centralization of tool maintenance, the company needed a solution that combines heavy-duty performance with flexible routing and fast availability. Radio remote control and multi-directional steering enable precise positioning and excellent maneuverability in day-to-day plant traffic.

Volkswagen

Volkswagen in Wolfsburg will rely on the HUBTEX SFX 65 going forward to safely and space efficiently transport press tools weighing up to 65 tons and coils weighing up to 32 tons within the press shop. The company was looking for a flexible alternative to rail guided systems, with all direction mobility, featuring both a flat load deck and a recessed coil pocket. HUBTEX delivered a customer specific version based on the standard vehicle platform.