Modern forklift trucks currently rely on three different types of drive: petrol, diesel or LPG with combustion engines (V-type forklifts), forklifts with electric motors (E-type forklifts) and industrial trucks with hybrid drives. Depending on the area of application and the requirements of that area, each forklift drive has specific advantages and disadvantages. Since petrol and hybrid drives are comparatively rare, the following article deals primarily with forklifts that are equipped with diesel and gas drives as well as electric motors.

Comparing types of forklift drive

Which forklift can be used where?

One of the most important features of a forklift truck is its drive concept. The type of forklift drive determines where the forklift can be used cost-effectively and to what extent. Forklifts with combustion engines are primarily intended for use outdoors, although modern LPG forklifts are now so low in emissions that they are also suitable for indoor use under certain conditions.

An overview of the areas of application for the various forklift drives:

- Diesel forklift: for outdoor use

- LPG forklift: for outdoor use, also suitable for enclosed indoor areas with sufficient ventilation

- Electric forklift: unrestricted use indoors and outdoors

- Hybrid forklift: primarily for outdoor use, limited use possible in enclosed areas

Advantages and disadvantages of the different forklift drives

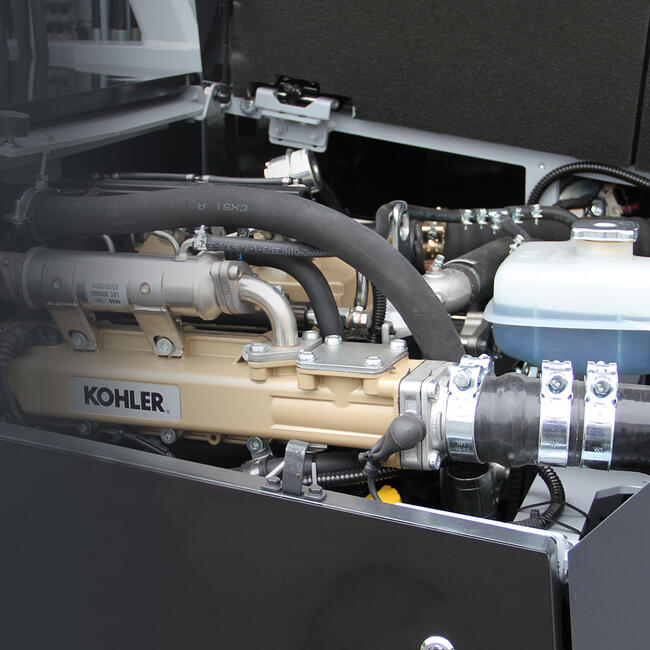

Diesel forklift

For intensive and demanding outdoor operations, diesel power –often used in four-way sideloaders – is the most popular choice.

Advantages of diesel forklifts

- High performance

- Drive type allows for easy refueling, no waiting time to charge batteries

- Well suited to 3-shift operation due to fueling opportunities

Disadvantages of diesel forklifts

- Only suitable for outdoor areas

- Comparatively high noise emissions

- Pollution of the environment from exhaust gases

- High expenditure for maintenance and repairs

- At best, modern diesel combustion engines have an efficiency of between 40 and 45%. For electric motors, this value is over 90% at nominal power.

- As well as poor efficiency, forklifts with diesel combustion engines have high losses when it comes to power transmission through a hydrostatic drive due to the high dissipation in the combustion process.

- Significantly reduced modulation due to the hydrostatic drive

Gas forklifts

Gas forklifts are available with liquid gas engines and with natural gas engines. Liquid gas-powered trucks are available in 2 variants, LPG and compressed gas forklifts. In contrast to diesel forklifts, LPG forklifts can also be used indoors if there is sufficient ventilation. Therefore, this type of forklift drive is advantageous, for example, in storage areas where battery chargers cannot be installed.

Advantages of gas forklifts

- Can also be used indoors under certain conditions

- Lower emissions and therefore more environmentally friendly than diesel trucks

- Forklifts with this type of drive are comparatively cheap to buy

- Gas cylinders can be changed quickly, ensuring high availability

- Well suited to 3-shift operation due to fueling opportunities

Disadvantages of gas forklifts

- Lower power than diesel forklifts

- Stringent requirements for the storage of the propellant gas cylinders in terms of occupational safety and fire protection

- Significantly reduced modulation due to the hydrostatic drive

- Efficiency is usually the same as that of a petrol engine (less than 40%), since the combustion system/engine concept is usually based on the petrol engine.

Petrol forklifts (forklifts with petrol engines)

The combustion of petrol produces, among other things, poisonous carbon monoxide, which is harmful to the environment and can be fatal to humans even in small doses. This can be prevented by using unleaded petrol and catalytic converters. Only petrol-powered forklifts equipped with a catalytic converter are permitted in enclosed spaces. In order to avoid accidents, special care is also required when handling the highly flammable fuel.

Electric forklifts

Forklifts with electric motors are the most popular choice when it comes to internal goods handling and transport within production halls and warehouses. Under certain conditions, electric forklifts, such as our multidirectional trucks, can also be good alternatives to forklifts with combustion engines. Since they operate very quietly, electric forklifts are particularly suitable for outdoor use in residential areas (mixed areas).

Advantages of electric forklifts

- Emission-free and environmentally friendly

- No loud noises or CO2 are produced during operation

- Low maintenance costs due to fewer assemblies, gearboxes and hydrostatic gearboxes

- Lower operating costs than diesel or LPG forklifts

- Less maintenance costs, no fuel storage required

- Very agile and easily manoeuverable

- Significantly better modulation due to the direct electric drive

- Very low losses in the traction drive increases efficiency during travel. For electric motors, this value is over 90% at nominal power.

- Significantly more efficient with regard to downtime, since only drives/motors that are actually needed are in operation. No continuously running combustion engines.

- Versatile applications

Disadvantages of electric forklifts

- Lower load capacity than diesel or LPG forklifts

- Suitable charging location and charging station required

- Battery life depends on usage, application and proper maintenance

- Only suitable for level, dry surfaces

- Replacement battery required for multi-shift use

- Time spent replacing the battery

Hybrid drives

In addition to the drive types mentioned, energy-saving forklifts with hybrid drives are also available. As with passenger cars, this type of forklift drive combines diesel drives with electrical energy storage devices (accumulators). However, the purchase costs of these models are significantly higher than conventional forklifts, therefore the investment is not worthwhile for every company.

Checklist to help you choose

the right forklift drive

Before deciding on a diesel, gas or electric forklift truck, the conditions and requirements of the site should be carefully considered. This is the only way to weigh up the advantages and disadvantages of the different drive types.

The following questions are designed to help you come to a decision:

- Will the forklift mainly be used indoors or outdoors?

- How long will the forklift be used at a time and how many shifts will the forklift regularly complete?

- How many operating hours is the forklift expected to complete each year? Will there be long periods of downtime between uses?

- What are the driving conditions like (surface, room for turning, aisles, etc.) in the application area?

- How would you describe the infrastructure on site? For example, power grid or energy supply?

- What weather conditions will the forklift be exposed to?

- What loads will the forklift be working with?

Forklifts for special requirements

In working environments with unique challenges, such as in cold stores or in dusty locations, it is vitally important to choose the right type of forklift drive. For example, in the food industry, various hygiene regulations must be observed, which electric forklifts fulfill far better than LPG or diesel forklifts. In comparison, there is a good reason why heavy-duty forklifts with load capacities of up to 80 tons are powered by LPG drives or are equipped with powerful diesel engines.