Find out in 5 steps.

Lamiplast optimizes hardware & DIY intralogistics

with the HUBTEX PHOENIX MQ multidirectional electric sideloader

Lamiplast is a Valencian company specializing in the distribution of materials for carpentry, kitchens, bathrooms, cabinets, flooring, and hardware, with multiple stores and warehouses serving both professionals and DIY customers. With a broad product range and growing demand, the company needed to store large volumes at height and make the most of every square meter of its facilities, while ensuring safe and efficient intralogistics.

The logistics challenge: vertical storage and narrow aisles

According to Pedro Espín, General Manager of Lamiplast, the company operates large facilities but with a clear requirement:

“We need to store goods at height. Even with large facilities, space is critical – and this machine gives us that space.”

Lamiplast’s collaboration with HUBTEX began after severe storm damage (DANA), which resulted in the loss of most of the company’s handling equipment. At that point, Lamiplast needed to replace a very old forklift and was looking for “something similar to what we already had, or something along those lines” – in other words, a solution well suited to warehouse operations with narrow aisles.

The logistics challenge can be summarized in three key points:

- The need to store large volumes of goods up to 6 meters long, including materials for carpentry, kitchens, bathrooms, cabinets, and flooring.

- Narrow aisles with fixed widths, where forklift maneuverability is critical.

- Replacing an outdated forklift with a modern, quiet, smooth, and highly maneuverable machine that precisely matches storage capacity and space requirements.

The HUBTEX solution

PHOENIX multidirectional electric sideloader for narrow aisles and high-level storage

To address these challenges, Lamiplast implemented a HUBTEX PHOENIX MQ multidirectional electric sideloader, configured specifically for its application.

The HUBTEX PHOENIX series consists of multidirectional electric side loader forklifts designed for handling long loads in narrow aisles and for maximizing storage capacity by reducing aisle widths. Thanks to the industry’s largest modular system, each truck can be customized precisely to the requirements of the application.

In Lamiplast’s case, HUBTEX analyzed the narrow aisles and space constraints in detail. Pedro Espín summarizes the process as follows:

“They adapted the machine to our needs – both in terms of maneuverability and storage capacity. They came, reviewed the facility, built the truck for us, and from day one it was simply put on the floor and ready to work.”

Compared to the previous forklift, the new machine represents a significant technological leap.

As Pedro Espín explains:

“The main difference compared to the previous truck is the technology. It’s extremely quiet, moves very smoothly, and is highly maneuverable.”

From the operator’s perspective, Jose Luis Bañuls noticed the difference immediately:

“This is my first experience with these trucks, and the difference compared to what we had before is very noticeable. It’s very digital, very smooth, and allows you to do things that other trucks simply can’t. Once you’re in the guided aisles, the truck moves on its own, and many movements that used to be fully manual are now handled automatically by the machine.”

Which multidirectional electric sideloader best fits your operation?

With the HUBTEX PHOENIX solution, Lamiplast benefits from:

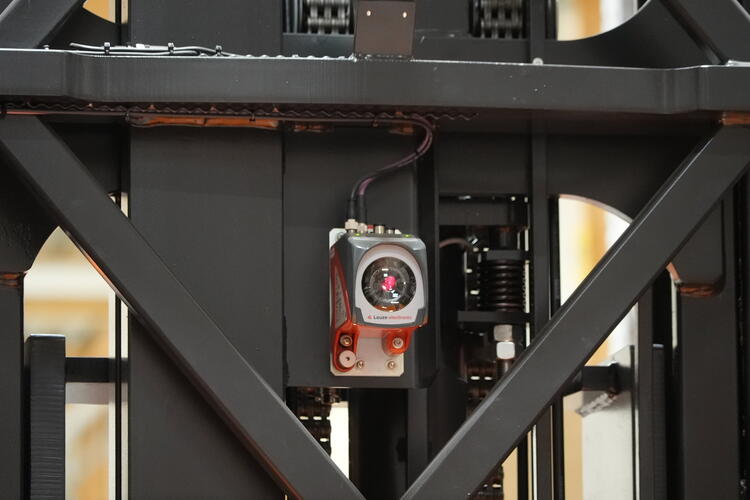

- A multidirectional electric sideloader optimized for narrow aisles, equipped with ultrasonic sensors for automatic aisle detection.

- A highly maneuverable and easy-to-handle truck, offering smooth and quiet travel.

- A forklift designed to maximize vertical storage capacity, precisely aligned with Lamiplast’s real-world storage and handling requirements.

The PHOENIX MQ used by Lamiplast features an automatic aisle detection system with ultrasonic sensors, which instantly aligns the wheels when entering the aisle. This increases safety, reduces unnecessary maneuvers in narrow aisles, prevents impacts, and speeds up high-level handling. Operator comfort is further enhanced by automatic guidance and a manual override button for maneuvering outside the aisle.

For high-lift applications, safety is essential. The PHOENIX MQ therefore includes a safety package that ensures stable handling even at great lift heights, automatically reducing travel and maneuvering speeds once the mast exceeds 3 meters. This protects both operators and goods in narrow aisles by preventing abrupt movements or unstable maneuver combinations. Thanks to this intelligent control, Lamiplast works with greater safety and precision at high rack levels.

Operational improvements achieved with HUBTEX

The benefits are reflected both in warehouse organization and in the daily experience of the team. For Pedro Espín, the new truck makes it possible to store goods at height in facilities where “space is essential, and this machine gives us that space.” HUBTEX adapted the solution “both in maneuverability and storage capacity,” and commissioning was immediate:

“From day one, it was simply put on the floor and ready to work.”

In daily operation, Jose Luis Bañuls highlights that the truck is “very digital and very smooth,” enabling tasks that were previously not possible. Once inside the guided aisles, the truck “moves on its own,” automating movements that were previously manual and significantly reducing operator workload.

In summary, Lamiplast achieves greater maneuverability in narrow aisles and benefits from a modern, efficient handling solution fully aligned with its operation. The company also values HUBTEX’s local service and technical support, including fast response times and reliable spare parts availability, ensuring quick intervention and operational continuity for a mission-critical machine.

Vertical storage and agile handling

in Hardware & DIY with the PHOENIX multidirectional sideloader

Door picking

aiming at the target with laser light

RWD Schlatter AG has significantly simplified the storage and picking processes for doors, door frames and raw materials. An individually configured HUBTEX MK15 electric multidirectional order picking truck drives semi-automatically to the individual rack compartments.

The efficiency gain is enormous: in the new warehouse of RWD Schlatter AG, a specialist in room and functional doors, only a single employee is required to pick the doors and frames at the Roggwil site. At the previous location, two people were needed for this process because at that time a conventional forklift truck was still used for this step. “To fulfill the orders, the desired doors had to be lifted out of the rack by the pallet, placed in the aisle and lifted off individually,” recalls Matthias Tabak, who works at RWD Schlatter as a group leader in production/logistics.

The company wanted to optimize its internal logistics by building a 295 in high warehouse with 210 pallet spaces, 18298 ft² of storage space on the ground floor and 21527 ft² on the basement level, and spoke in advance with potential suppliers – including Rohrer-Marti AG, which acts as the Swiss importer and service partner of HUBTEX. As early as 2021, ideas and possible solutions for simplified order picking were discussed with Rohrer-Marti and the specialists from HUBTEX. The result was a HUBTEX MK15 electric multidirectional order picking truck that was individually customized for RWD Schlatter and can also take over the storage of wooden pallets weighing up to 3307 Ibs to a maximum lifting height.

All special requests taken into account

The vehicle was delivered in April 2023 - just one month after completion of the new hall, which has four rows of racking and two aisles.

“The project with HUBTEX went very smoothly and professionally. All of our special requests were taken into account,” confirms Peter Seitz, Head of Project and Process Management. Only seven months passed between the order and delivery of the device. The only thing that was faster was the second forklift truck that RWD Schlatter needed for the new hall in the basement: a HUBTEX Phoenix MQ35 multidirectional sideloader for the raw materials warehouse was available after just six months.

The 153 in long MK15 is controlled by joystick, either from a seated or standing position, and has an order picking platform with an operating stand. The platform enables order picking on both sides and can be raised to a height of 291 in. In front of it, in the direction of travel and view, are the two telescopic forks, which can be extended on both sides and are also height-adjustable together with the load table. This initial lift always allows the picking pallet to be brought into an ergonomically favorable position when processing orders with up to 30 items. The two-part pendulum chassis ensures that all four wheels are in constant contact with the ground thanks to the mechanical level compensation.

Option for the future

The next order item of the current picking order is shown to the operator on a display connected to the company's own warehouse management system in the ERP system via WiFi. To reach the destination, the operator simply has to enter the corresponding rack compartment address on the HUBTEX positioning terminal. The MK15 moves through wire guidance within the only 40 in wide rack aisles. Around 7874 inches of induction wire were laid in the hall floor for this purpose. After the destination address has been entered, the electric multidirectional order picking fork lift truck moves semi-automatically to the shelf compartment. To measure the horizontal position in the aisle, a distance sensor mounted on the lift arm sends a laser beam to a reflector plate mounted at the end of the aisle.

As soon as the horizontal target position is reached, another vertically measuring laser sensor is activated: This measures the current lifting height and detects when the respective storage compartment has been reached with a maximum deviation of 0,79 in. The operator now moves the load table or the picking pallet to the correct height using a joystick, with the help of two cross-line lasers. The required item is then removed from the compartment. In order to make it easier to move the heavy doors, supporting rollers can be inserted on the loading table. As soon as all the doors for an order have been picked up, the picking of the frames that are stored in the neighboring aisle begins.

Precise operation

“Working with the MK15 is very precise and easy to understand, which makes it possible to learn the ropes quickly,” reports Antonio Mancuso, who mainly operates the machine and can use it to complete up to 300 picking orders every day.

As soon as the truck is in the lane, the four wheels automatically align themselves for lengthwise drive. With the help of two cameras and a flat screen mounted in the center under the protective roof, the operator can see the route ahead. In addition, a personal protection system integrated into the forklift with laser scanners installed on both sides prevents the MK15 from endangering people or objects in the aisle. When an obstacle is detected, the MK15 is automatically braked. The truck cannot move off again until the person has left the danger area or the object has been removed.

Conclusion:

RWD Schlatter AG has significantly simplified its internal logistics with the individually configured MK15 electric multidirectional order picking truck. The storage and picking processes can be carried out in less time with only half the manpower required for the previous process. This is a major advantage in view of the increasing shortage of skilled workers. In addition, the new hall has a very high storage density because the aisle widths could be reduced to only 4 in.

Discover the benefits for your application

Depending on the turnover rate, storage capacity and budget, there are various solutions for picking long, heavy and bulky goods. Let our product experts advise you on the right picking solution for your application.

What does RWD Schlatter AG say?

Background: RWD Schlatter AG

RWD Schlatter is a Swiss full-service provider of sustainably manufactured functional doors with safety options such as fire, smoke, sound or burglary protection, as well as interior doors combined with high design standards. With around 200 employees in Switzerland, RWD Schlatter is able to serve the entire value chain from development and production to installation and maintenance.

The company, based in Thurgau, has established a leading position in the Swiss market for building security and is considered a reliable partner for efficient, high-quality complete solutions in construction. With its smartDoors (keyless entry system), digiDoors (which documents, controls and automates the lifecycle of doors) and “service” QR code on every door, RWD Schlatter is also playing a pioneering role in the digitalization of doors. Around 90,000 custom-made wooden doors are produced annually at the headquarters in Roggwil, Thurgau. The history of RWD Schlatter can be traced back to 1884. Since 2007, RWD Schlatter has been part of the Arbonia Group, headquartered in Arbon, Thurgau. Further information can be found at www.rwdschlatter.ch.

Background: Rohrer-Marti AG

Rohrer-Marti AG is one of Switzerland's leading importers of forklift trucks and construction machinery. Since its foundation in 1946, the company has grown steadily and now employs 65 people. The company is present in Zollikofen BE and Echallens Payerne VD and represented throughout Switzerland by regional partners.

The exemplary spare parts service and seamless service organization ensure that all customers can use their forklifts and construction machines without any problems at any time.

Automation at HUBTEX

The handling of long, heavy and bulky loads is the core expertise of HUBTEX Maschinenbau GmbH & Co. KG. For at the beginning of 2020, the company is planning to launch for the first time an Automated Guided Vehicle (AGV) specially designed for handling long goods.

MaxX by HUBTEX wins the FLTA Award 2019

In 2019, Fulda-based company Hubtex won the international FLTA Award 2019 in the category "Ergonomics" with its MaxX electric multidirectional sideloader. The award is presented annually by the British Fork Lift Truck Association in Telford (UK). In addition, the MaxX also received the “Best in Intralogistics” certificate for 2019 as part of the IFOY Awards.

New heavy-duty compact frontlift RoxX

Frontlifts are often the vehicle of choice when handling heavy loads, but when used in tight spaces, they quickly come up short. Providing a robust and manoeuvrable solution to this challenge is the RoxX, a line of heavy-duty compact frontlifts supplied by Hubtex.

Major load-carrying capacity with universal range of applications - FluX 70

The handling of timber materials poses major challenges for manufacturers of forklifts and industrial trucks. Innovative solutions are required to ensure the safe transport of long, heavy and bulky goods, especially on uneven surfaces and in tight aisles. Hubtex has expanded the field of application of its FluX model, with the electrical multidirectional sideloader now able to handle loads weighing up to 7 tonnes.

Omnidirectional EPL material lifter and work platform from Hubtex

As global air traffic continues to increase, so too does the need for aircraft. In the field of aircraft construction and maintenance, there is a high level of demand for smart solutions that ensure efficient work processes and thus help to reduce production and maintenance costs. This is where Hubtex comes in with its mobile material lifter and supply platform from the EPL series.