Collision risk in narrow aisles: HUBTEX introduces Clear Aisle Assist

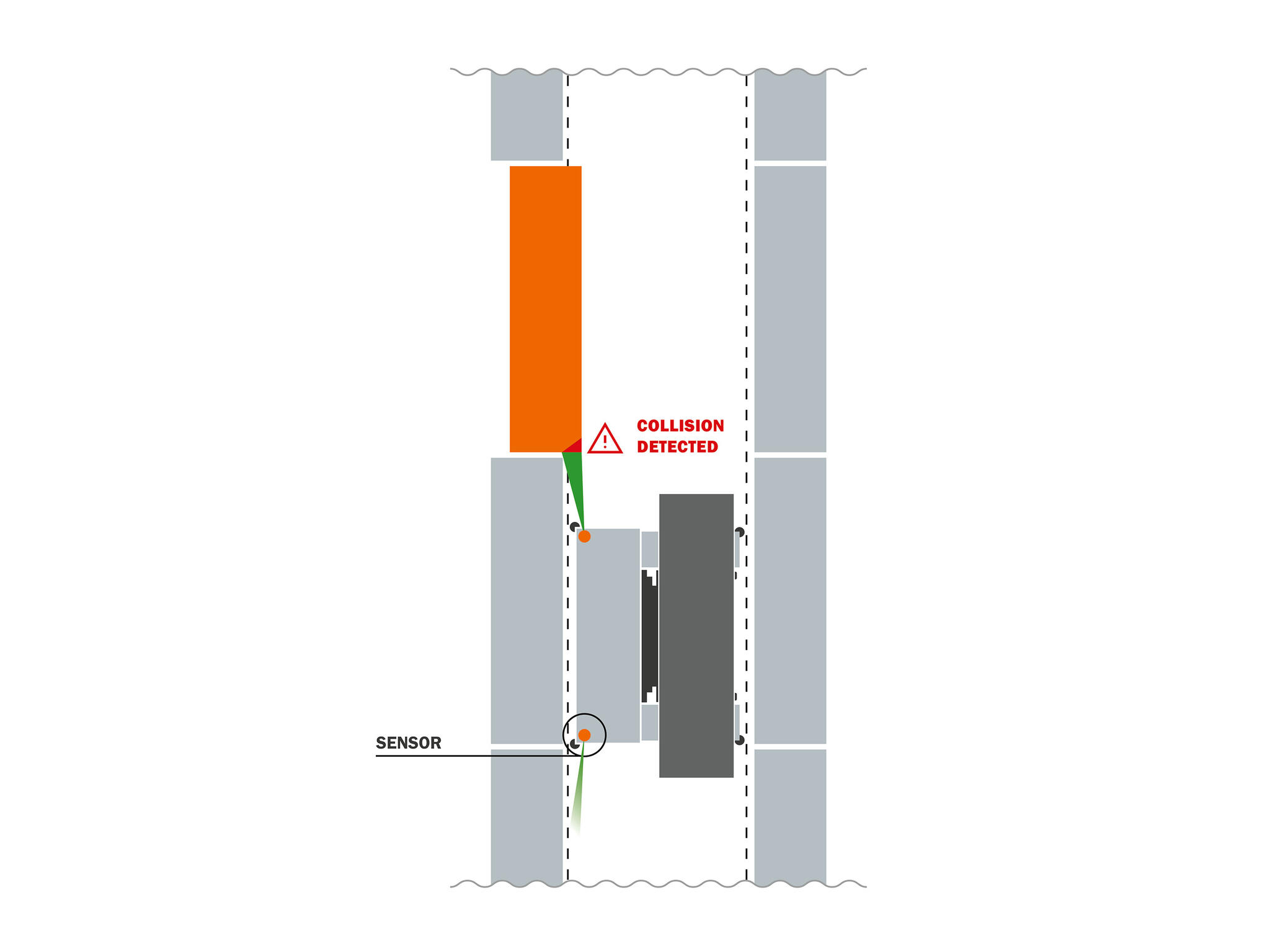

In narrow-aisle warehouses, multidirectional forklifts often operate with minimal safety distances. Collisions with protruding loads pose a constant safety risk. To effectively minimize this risk, HUBTEX has developed the patented Clear Aisle Assist: A system of laser sensors that identifies protruding loads in the aisle, alerts the driver, and automatically reduces speed.

Challenges in narrow aisles: minimal clearance, limited visibility

HUBTEX multidirectional sideloaders are frequently utilized in narrow-aisle warehouses. To maximize storage capacity, these vehicles operate within guidance systems with very limited safety clearance, often with less than 4 inches on each side. This increases space efficiency but restricts the driver’s visibility. It becomes particularly critical when long goods are stored at an angle or when neighboring loads are inadvertently moved during retrieval. Parts may protrude into the aisle and aren't always seen by the driver until it is too late, especially on the engine side. This can lead to contact issues and costly damage to the chassis, battery, cabin, or rack system. In the timber, metals, and general industrial trade, with hundreds of moves per day, this scenario is commonplace.

Patented solution: monitoring with laser-based sensors

To reduce these risks, HUBTEX has developed the Clear Aisle Assist, which oversees the vertical danger zones along rack systems and reacts automatically if needed. The system utilizes Lidar sensors to assess vertical planes in the vehicle's environment. Sensors are mounted at suitable positions based on vehicle configuration and scan both forward and in reverse. This ensures early detection of protruding loads, whether the sideloader enters the aisle forward or backward. The monitored area dynamically adjusts to key parameters, with speed, lift height, and configuration determining the size of the protective zones. This allows for precise, needs-based detection of potential collision zones without burdening the driver with additional tasks.

Classification: The Clear Aisle Assist does not replace personal protection technology but supplements it with collision protection for loads protruding from the rack system.

Now available for the PHOENIX series

If the system detects an obstacle, it issues a warning first. If necessary, the system automatically reduces speed to avoid contact or minimize its consequences. The goal is an assistance system that effectively enhances the driver's focus and maintains material flow in tight layouts. "Our aim was to develop an assistance system that actively supports the driver without adding extra burden," states Michael Röbig, Head of Product Management at HUBTEX. "The Clear Aisle Assist recognizes dangerous situations early and, if needed, can not only warn the driver but also automatically reduce the vehicle's speed." The system is now available for the PHOENIX series and complements existing personnel protection scanners by providing protection against goods protruding into the aisle.

Meet the Clear Aisle Assist at the MODEX

HUBTEX will provide details about Clear Aisle Assist at the upcoming MODEX on April 13-16 in Hall A, booth A3827