Clear Aisle Assist

Reduce Repairs & Downtime in Narrow Aisles with LiDAR Collision Avoidance

Available with all

Available with all

PHOENIX series Detects protruding loads, prevents collisions

Detects protruding loads, prevents collisions Fewer repairs, more uptime

Fewer repairs, more uptime

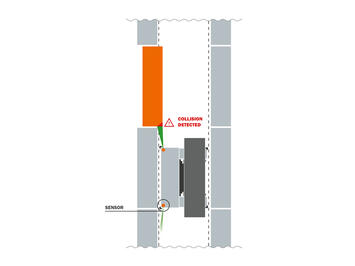

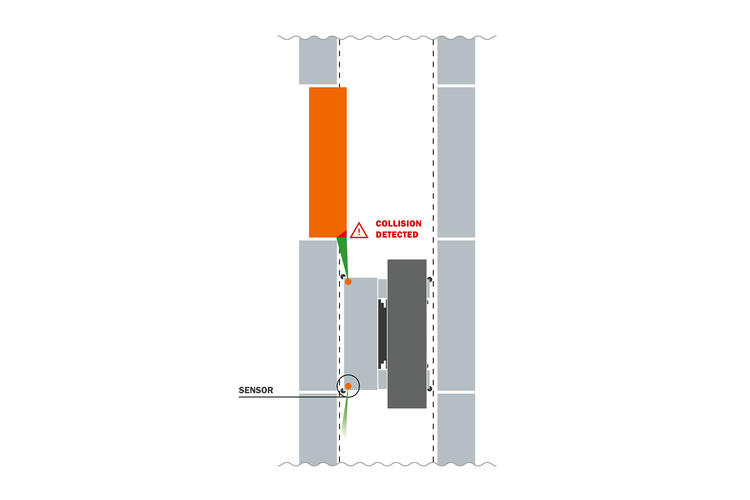

Narrow-aisle long-load storage leaves little room for error: protruding bundles or profiles on the racks can enter the travel path of the sideloader and cause costly impacts. Clear Aisle Assist solves this with dual LiDAR sensors that monitors the aisle, warns the operator, and if required, automatically slows the PHOENIX multidirectional sideloader to prevent a collision.

- Detects protruding loads in both travel directions in narrow aisles with vertical LiDAR sensor system

- Auto slow to prevent collisions; protects racks, goods, cabin & hydraulic compartment of the sideloader

- Fewer repairs, more uptime

- Supports operators without extra workload; assistance triggers automatically

- Patented and now available for all Phoenix Multidirectional Sideloaders

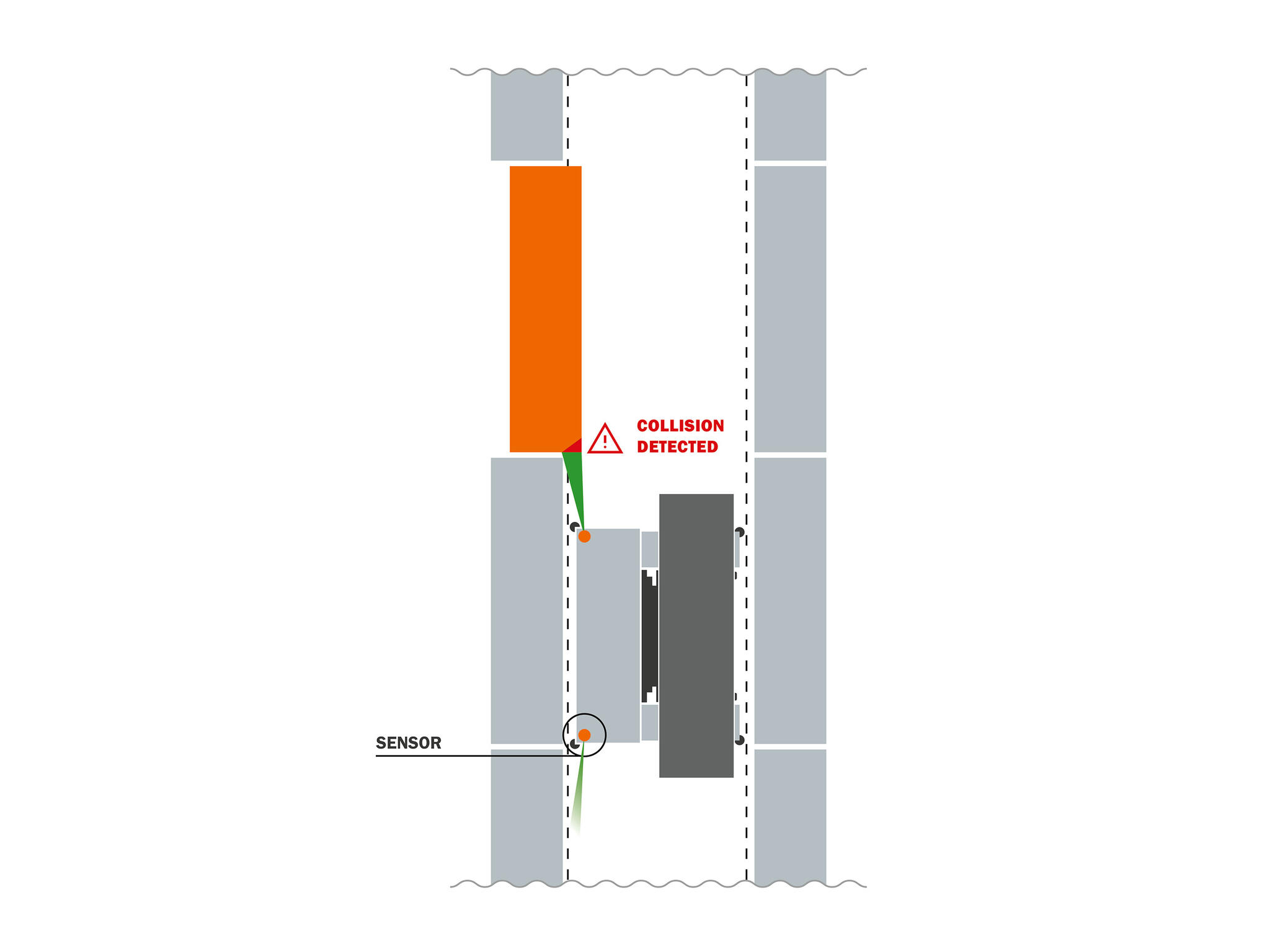

The challenge in narrow aisle warehouses:

tight spaces, limited visibility, high collision risk

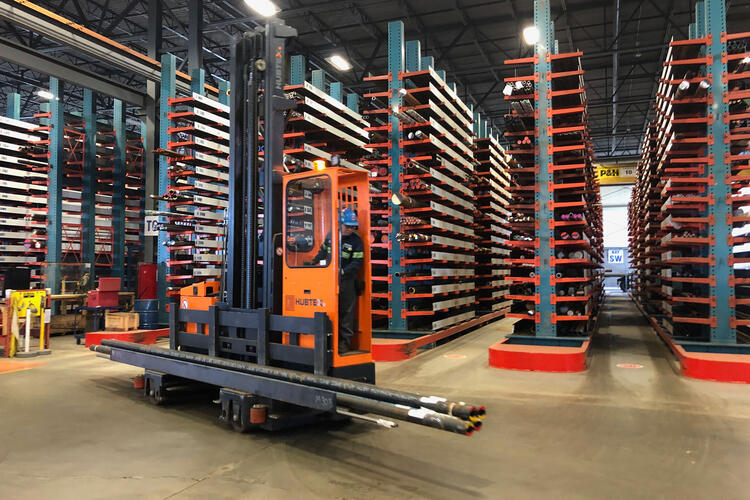

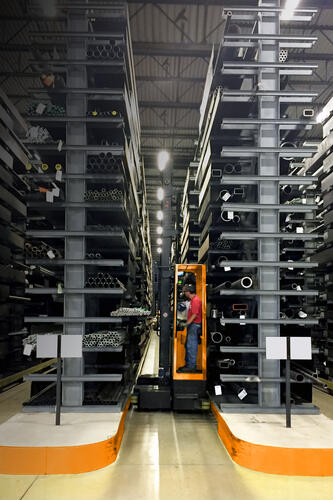

In warehouses for long load handling, HUBTEX multidirectional sideloaders frequently operate in narrow aisles with guiding systems and minimal safety clearances— often <4 in per side to maximize storage capacity. Even with lift trucks optimized for this environment, operator visibility can be limited. During storage, croocked or mis-positioned timber, steel, plastics, or aluminum bundles or profiles can protrude beyond the rack—especially hazardous when the sideloader approaches with the cabin side. These hard-to-spot obstructions raise the risk of impacts to the truck's cabin/hydraulic area, chassis, or battery, causing safety incidents, damage, and downtime.

The solution: Clear Aisle Assist

patented LiDAR aisle monitoring for maximum safety in warehouses

Clear Aisle Assist is a patented, LiDAR-based driver assistance system that performs intelligent environment monitoring in narrow aisles. Strategically placed laser sensors (configured per truck) scan both driving directions within the aisle to detect protruding loads and obstacles early - even in complex racking layouts. The monitored zone adapts dynamically to vehicle parameters such as travel speed and lift height; typical settings align the scan height to the cabin. When an obstruction is detected, the operator receives a clear visual cue under the display and, if required, the speed of the multidirectional forklift can also be automatically reduced in order to avoid impact. Designed to support operators without adding workload, Clear Aisle Assist increases warehouse safety and uptime, and is available for the HUBTEX PHOENIX series.

Safer Aisles. Fewer Repairs. More Uptime.

Let’s evaluate your working aisles and PHOENIX fleet to configure Clear Aisle Assist for maximum safety and uptime.