Skip and container

transport

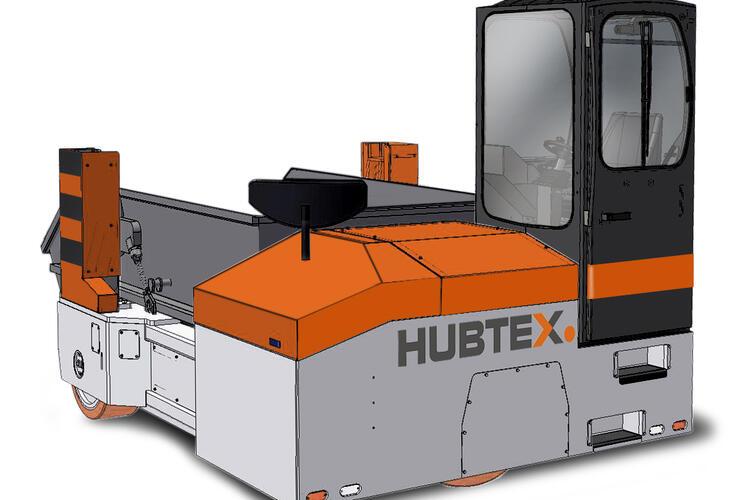

by HUBTEX

Load capacity up to 25 t

Load capacity up to 25 t  Various

Various

load-handling

variants Adaptable to all

Adaptable to all

applications

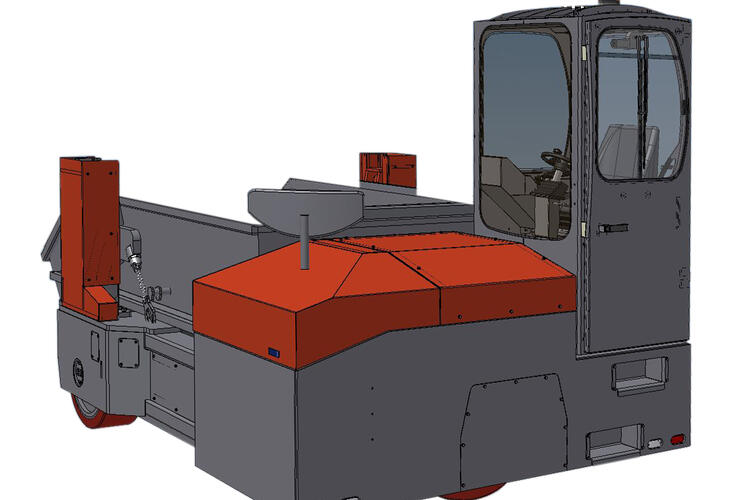

Wastewater treatment plants, waste incineration plants and waste disposal plants rely primarily on skips and containers as load carriers in their logistics. For overall economical processes, these quickly reach a weight of more than 10 tons, which can no longer be handled efficiently with standard lift trucks in the container station or outside areas. HUBTEX has therefore developed its own skip and container transporter with a load capacity of up to 25 tons especially for this area of application. These can also be individually adapted to their place of use, for example in the Koblenz wastewater treatment plant.

Individual container sizes

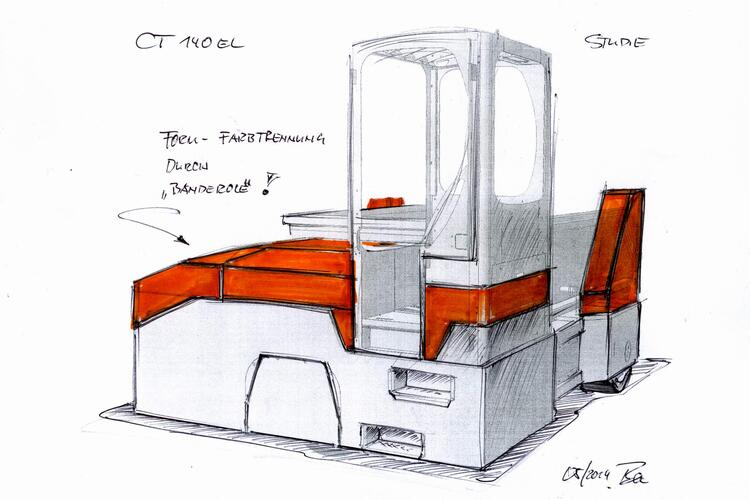

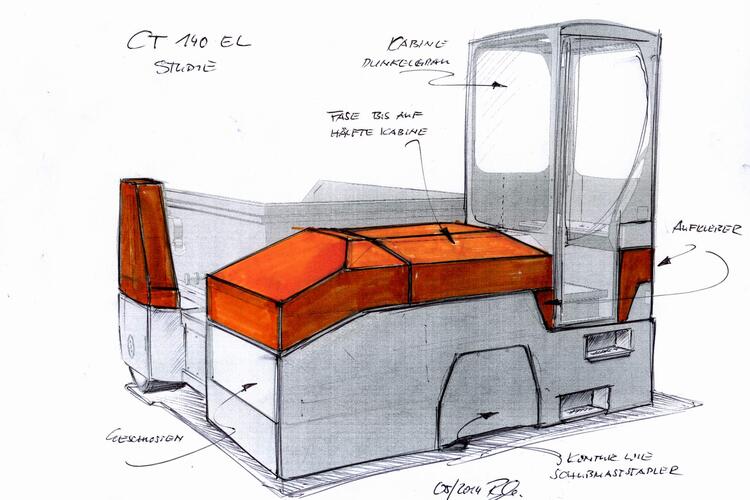

To respond precisely to the wishes and requirements of our customers and to design special-purpose vehicles accordingly – that is the claim made by HUBTEX. The HUBTEX container and skip transporters can be individually adapted to different container sizes for any customer.

Operation report – Special trucks for waste disposal logistics

The first place of use for the HUBTEX CT 140 with a load capacity of 14 tons is the container hall at the Koblenz wastewater treatment plant. Important factors for the customer when making its decision were the low construction and lift height of the transporter and its 3-wheel chassis, which provides more stability during transport.

Even with poor ground conditions, the vehicle maintains contact with the ground, bringing the skips safely to their destination.

Features

The special-purpose vehicle manufacturer HUBTEX offers its skip and container transporters in three variants.

- Swivel arm / carrying rails

- lifting cables

- Fork handling

When the load is picked up with the swivel arm / carrying rails, the skip is bypassed, the swivel arms extend, are fixed in place and then lift the skip. The driver does not have to leave the vehicle during this process.

With the load lifting variant using lifting cables, the truck bypasses the skip, the lifting sling is hitched manually on both sides and the load is then lifted.

With the third variant, the skip is lifted and transported by forks. The lifting process requires accurate work and precision, among other things.

Depending on the application, individual frame production and corresponding cab variants are possible. The driver’s seat is positioned at 90° to the load. This puts the cab in an optimum position with low entry height and excellent all-round visibility during travel and load pick-up. Along with the vibration-damped cab, this makes comfortable working possible. The perfectly configured operator terminal enables precise maneuvering of the vehicles.

The vehicle is based on a three-point chassis which, due to its small turning radius, can even be maneuvered through complex bottlenecks without any problems. In addition, it provides stability during transport, even in poor ground conditions, as it maintains contact with the ground at all times.

Due to the choice of three different tire variants PU-soft, PU and EL, our container and skip transporters can be used in combined indoor and outdoor applications.

The best advice can be found here.

We know that the handling of skips and containers presents users with special challenges. Arrange a non-binding consultation appointment with our specialists to get the best possible solution for your application.