Timber transport

HUBTEX supplies multidirectional sideloaders and order-picking systems to timber wholesalers, sawmills, wood-processing companies, kitchen manufacturers, prefabricated house builders and many other companies all over the world.

Customers use our vehicles to transport a wide variety of loads: In addition to chipboard, decors and laminated beams, these also include construction and sawn timber as well as kitchen worktops and doors.

Task areas

Electric multidirectional counterbalance forklift

The FluX is a counterbalance forklift for the combined handling of pallets and long goods in equal parts. It is therefore ideal for transporting long and bulky goods, as is often necessary in the timber industry.

The FluX is particularly characterized by its patented steering system with smooth changes of direction in combination with the compact frame length and the fixed lift mast. The intelligent and energy-efficient drive concept makes it unbeatable in its class.

Electric multidirectional sideloader (3-wheel)

The HUBTEX DS 30 represent the entry-level variants of the electric multidirectional sideloader. Due to its predominant use in retail or in manufacturing companies, it is also the right solution for the timber industry. Its low entry height allows fast entry and exit of the vehicle. Loads of up to 3000 kg can be transported in narrow aisles in combined indoor and outdoor applications.

Electric multidirectional sideloader

The HUBTEX electric multidirectional sideloader is a true multitasker. It can be used in almost every sector. Whether in the basic version, as a vehicle with an assistance system or as a fully automated transport system. The electric multidirectional sideloader can be used for almost all application scenarios. Its multidirectional steering enables optimum maneuverability to be maintained. The distance between the rack rows is minimized while the storage capacity is simultaneously increased.

Electric multidirectional sideloader with removable order picking platform, KP series

The basic variant of the electric multidirectional sideloader is already configured for handling long loads in narrow aisles.

The addition of an order picking platform quickly transforms it into an order picking vehicle. The operator controls the system from the platform. Another operator can manually pick the wood sheets directly onto the vehicle.

Electric double-sided order-picking platform, MK series

The series is ideal for the stacking and order picking of doors and frames. The conventional electric multidirectional sideloader with man-up cab is therefore optimal for the picking of customer orders.

EZK electric double-sided order picking platform with 2-mast lift or scissor lift

The EZK order picking platform is particularly suitable when high handling capacities are required. The platform is characterized by a two-sided rack operation. The vehicle scores with its wide range of equipment variants, such as automatic vehicle positioning in the aisle as well as centering in front of the load or enabling the goods to be strapped on the vehicle.

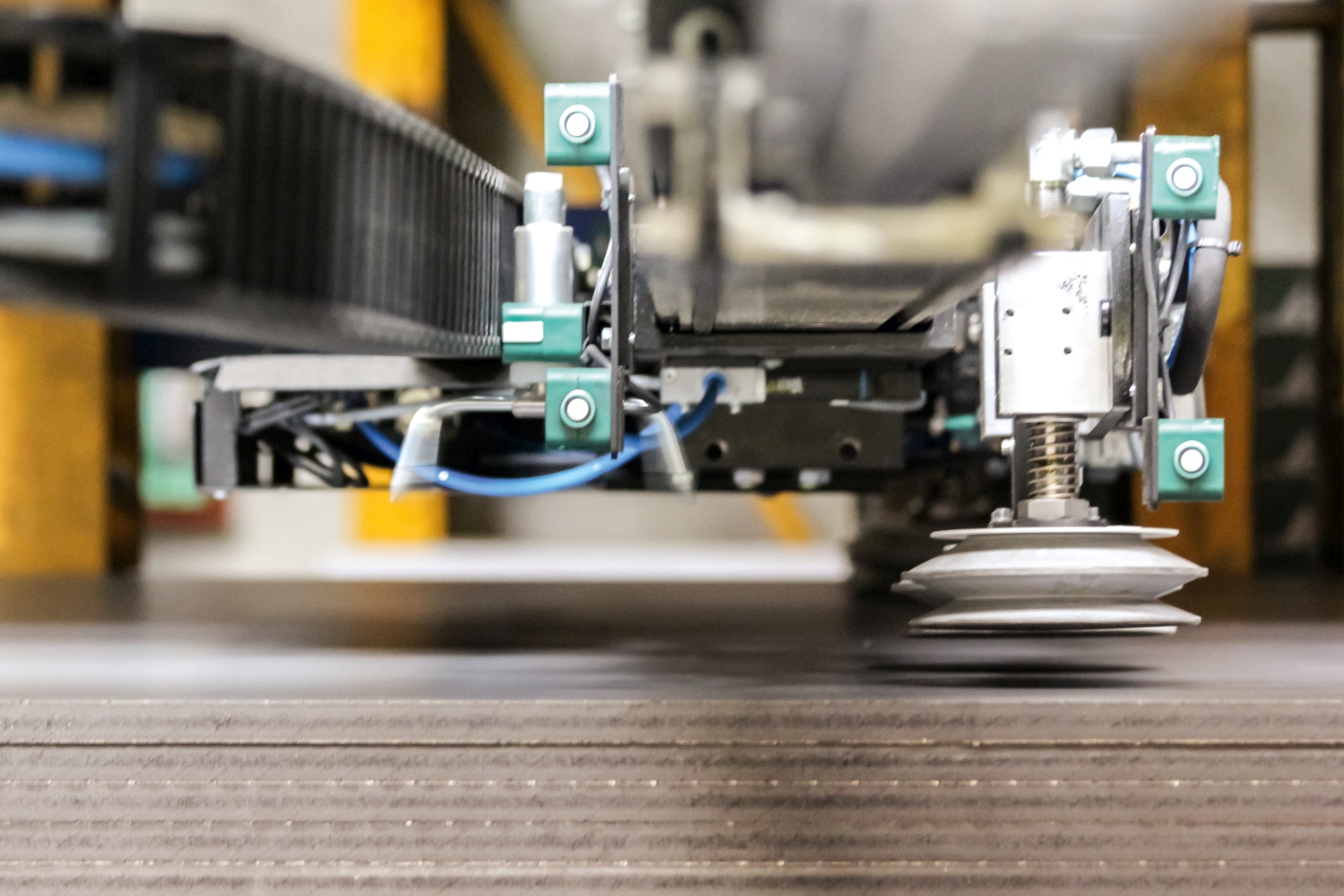

Vacuum suction technology

Each order picking platform can be supplemented with the VacumaX vacuum suction device from HUBTEX. With the help of the extendible suction cups, individual sheets are picked from the rack and then set down on the vehicle. Heavy loads are moved safely, keeping material damage to a minimum.

We know the best solution.

We know that handling heavy loads in confined spaces presents users with special challenges. Arrange a non-binding consultation appointment with our specialists to obtain the best possible solution for your application.

CASE STUDIES

What our customers and partners say about our products and services.

Volkswagen

Volkswagen in Wolfsburg will rely on the HUBTEX SFX 65 going forward to safely and space efficiently transport press tools weighing up to 65 tons and coils weighing up to 32 tons within the press shop. The company was looking for a flexible alternative to rail guided systems, with all direction mobility, featuring both a flat load deck and a recessed coil pocket. HUBTEX delivered a customer specific version based on the standard vehicle platform.

Ryerson Inc.

Ryerson uses a HUBTEX SFX 40 platform transporter in its Coil Processing Center to move coils weighing up to 30 tons safely and in a controlled manner throughout the plant. Rather than relying on permanently installed rails, the focus is on a flexible solution that makes narrow routes and day to day pedestrian traffic easier to manage. Radio remote control operation and the integrated safety concept, featuring sensors and warning signals, help to noticeably enhance safety standards in the immediate work area.

AGC Seapane

At AGC Seapane in Zeebrugge, Belgium, two HUBTEX multidirectional sideloaders move empty and loaded glass racks every day between the warehouse, the loading bay, and external storage areas, as well as for truck loading. One HUBTEX MQ 30 has been in operation for almost 15 years. Since early 2024, the fleet has been expanded with a PHOENIX MQ 30 featuring 3-ton capacity and multidirectional steering. After trialing a competitor truck and then returning to the proven technology, this combination delivers high availability, short transit times, and consistently stable operations.