Side Loader Forklifts

for Long Loads in confined Spaces

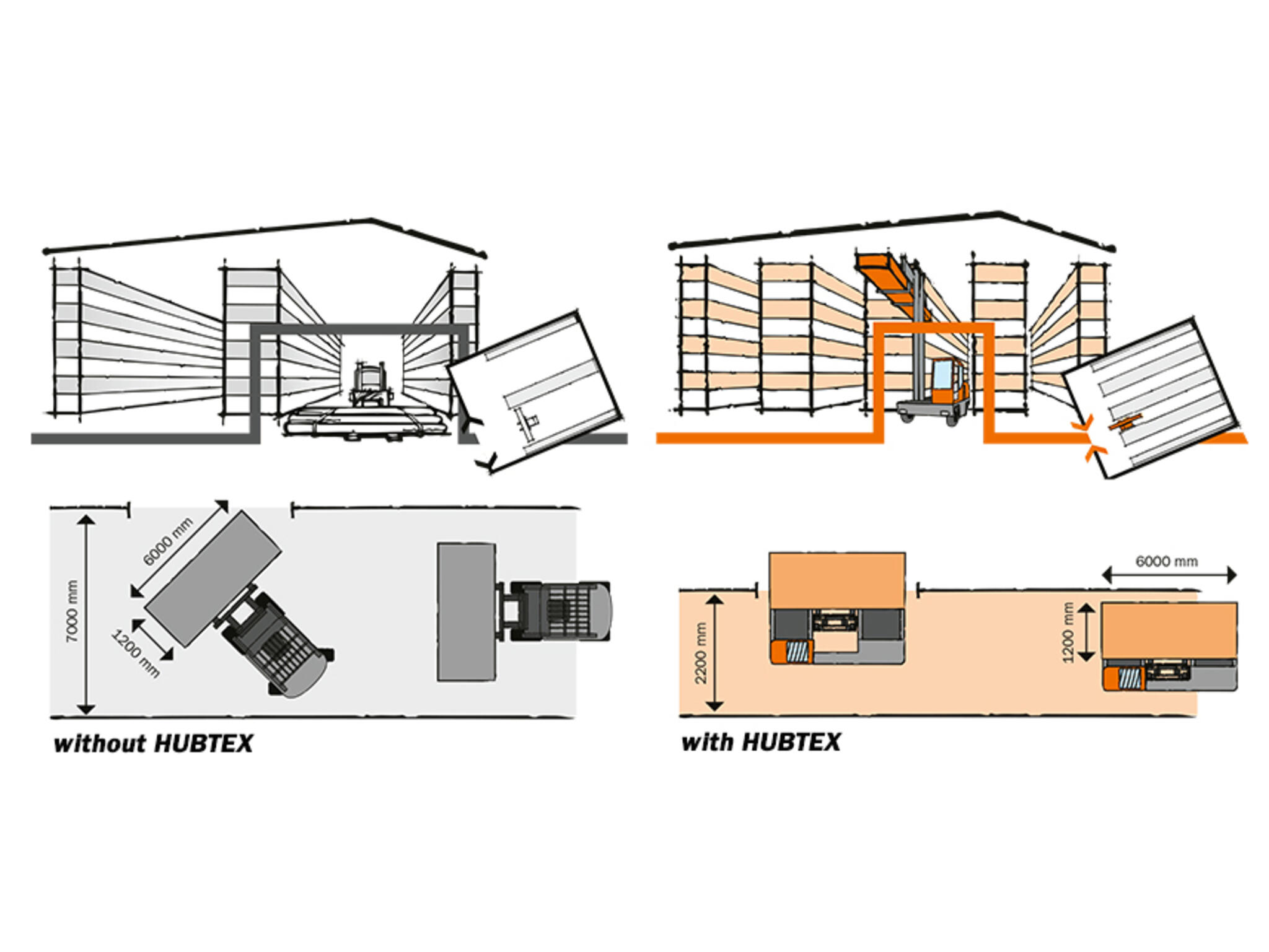

Side loader forklifts are the go-to solution for handling long and bulky loads in warehouses and yards. Unlike conventional forklifts that transport goods in front of the vehicle, sideloaders lift loads from the side—enabling efficient operation in narrow aisles and maximizing available storage space.

By picking up materials sideways, sideloaders reduce the need for wide racking rows, allowing more aisles to fit within the same footprint. This makes them ideal for transporting items like timber, steel tubes, and plastic profiles. Whether in indoor or outdoor environments, sideloaders help optimize workflows, improve safety, and increase warehouse capacity.

HUBTEX Sideloader Types

Which sideloader is right for you?

Find out in 5 steps!

What Makes a Side Loader Forklift the Right Choice?

Save money, space, and time.

Our side loader forklifts are ideal for indoor and outdoor use, especially in warehouses or yards where space is limited. Thanks to advanced features such as multidirectional steering and high load capacities, HUBTEX sideloaders improve safety and reduce handling time.

We offer a wide range of models, including:

Electric sideloaders for emission-free operations

Multidirectional sideloaders for enhanced maneuverability

Narrow aisle side loader forklifts for tight racking systems

Lateral forklifts for long-load handling

Side lift forklifts tailored to specific industry needs

Whether you're moving 7 m long timber or managing heavy pipes, a HUBTEX side loader forklift helps you make better use of space while minimizing wear on materials.

Sideloaders with multidirectional steering

The maneuverable specialist

The side loader forklift with multidirectional steering is ideal for indoor and combined indoor/outdoor use. Its independently suspended wheels allow for seamless movement in all directions—forward, backward, sideways, diagonally, and even in circular patterns. The smooth transition between travel modes enables precise maneuvering, especially in tight spaces.

Thanks to its compact wheels, low load arm height, and small turning radius, this sideloader can navigate the entire warehouse—even areas with low racking. Loads from the lowest rack levels can be accessed with minimal lift effort, while the high-lift mast also enables handling at racking heights of over 10 meters.

These features make the sideloader especially suitable for narrow aisles and confined environments. The PHOENIX truck can be highly customized:

Aisle guidance systems allow for precise positioning

Operator safety is supported by adaptable assistance systems

The driver's cab can be tailored to match specific operational needs

On solid ground surfaces, elastic tires allow for reliable performance outdoors as well. For advanced applications, automation options are also available.

Which sideloader is right for you?

Find out in 5 steps!