Aviation

HUBTEX industrial trucks are used at various points of the aviation value chain. These vehicles offer numerous options for individualization and can be seamlessly integrated into the respective logistics or production process. The intelligent use of fully and semi-automated solutions is key to the resource-efficient manufacturing planning offering significant reductions in production delivery times.

Task areas

AGV STANDARD LIFT PLATFORM TRANSPORTER (SL-AGV)

Platform trucks and rail-mounted trucks are self-propelled vehicles that transport loads with the help of their large loading platform. They are used for the handling and transport of all types of heavy loads. In the aviation industry, for example, these include wing segments, fuselages, work platforms and other components. The platform trucks can also be interconnected to form a system with a higher load capacity; they are controlled via radio remote controls. So in coupled operation, the HUBTEX fuselage transport trolleys can transport heavy aircraft fuselages weighing up to 70 tons from one assembly spot to the next.

FUSELAGE TRANSPORTERS (FTT)

Another option for transporting fuselages is the fuselage transporter (FTT), where a tractor is mounted on the nose wheel. This is used to steer the fuselage. The transport trolleys are attached to the later position of the landing gear. The FTT is equipped with an auxiliary steering system for exact positioning at the next assembly location.

AGV HIGH LIFT PLATFORM TRANSPORTER (HL-AGV)

The HUBTEX HL-AGV platform truck lifts work platforms when coupled with a second vehicle. The target position under the load is approached accurately and collision-free with the aid of a sensor-supported assistance system. In coupled operation, both HL-AGVs are controlled via one control panel located on the work platform. Sensitive movement through multidirectional steering and lifting are now always synchronous and purely electric. The work platform can be lifted up to 6.5 meters.

OMNIDIRECTIONAL VEHICLE (ODV)

As an alternative to mobilizing work platforms, our omnidirectional vehicles (ODV) can be docked to work platforms. In coupled operation, several ODV can move a work platform. In addition, the vehicles can be used as conventional tractors in production.

DRIVE AND LOAD UNITS (WDU AND WU)

An innovative automation solution in the aviation industry is the combination of the electrically steered WDU drive units and WU load wheel units. These units can be retrofitted to existing stationary work platforms in order to upgrade them to a mobile system through the coupling operation. This drive concept is completed by an electric cabinet, a lithium-ion battery as well as a radio remote control to operate the chassis. With the help of the specific multidirectional steering electronics, precise positional movement of the load is now possible in all directions. Depending on the load capacity requirements, the WDU and WU can be extended to up to 16 units, allowing a maximum system load of up to 125 tons to be moved.

TWIN-LINKED SIDELOADER RIDER TRUCK (TLSRT)

The coupling operation of two vehicles is one way of transporting very heavy loads, such as wings or fuselages. The load is absorbed by both vehicles at the same time. They then connect to each other under Bluetooth control. This creates a stable transport system with double the total load-bearing capacity. Both systems are in permanent communication during transport and can be operated together via a radio remote control.

ELECTRICAL PLATFORM (EPL)

HUBTEX EPL assembly and work platforms are used in various work steps within aircraft construction. They reliably bring the fitters and the material to the desired position. These self-propelled, omnidirectional freight elevators with load capacities of up to 5 tons are electrically driven and can be controlled via radio remote control or workstand. The vehicles are optionally available with slow and line-moving functions. Optionally, the vehicle can be manufactured in a 2-mast or 3-/4-mast version. The advantage of the 4-mast lift system is that one part of the platform remains firmly positioned on the aircraft, while the other part functions as a goods elevator. All vehicles of this type are prepared for automation in AGV operation.

ELECTRIC MULTIDIRECTIONAL SIDELOADERS

HUBTEX multidirectional sideloaders are individually adapted to the requirements of the aviation industry. Typical applications for multidirectional sideloaders can be found in many sections of the aviation value chain handling long and heavy loads. Be it in the warehouse or production logistics, the prefabrication of aircraft segments or handling of mold carrier systems for GRP parts, tools or finished components, through to assembly support or finally in spare parts logistics.

TOOL CHANGERS

HUBTEX tool changers are used for changing pressing and punching tools, handling injection molding tools or individual GRP mold carrier systems – and adapted individually. Tool changers boast compact vehicle dimensions and low entry heights under the tools, but can handle loads of up to 65 tons.

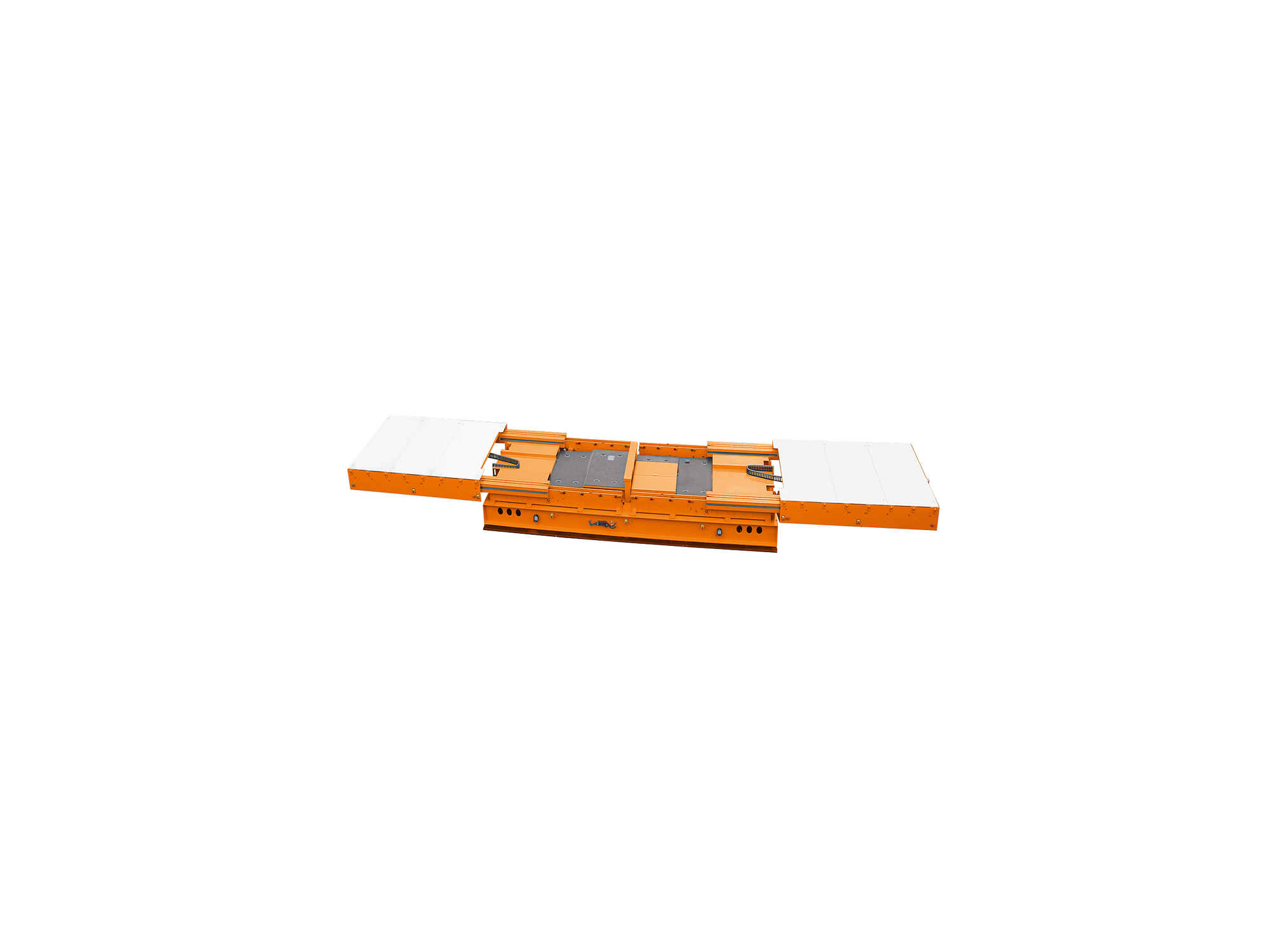

Platform transporters (SFB)

The SFB platform transporter is operated via radio remote control and, if required, the vehicle can be automated. It has a chassis with multidirectional steering, with which heavy and bulky loads such as entire segments of an aircraft can be precisely maneuvered, even in the most confined spaces. With its modular design, the platform truck covers a large number of applications. The modular principle enables users to combine the desired equipment variants as well as assistance and personal protection systems. For special transport tasks, such as the transport of wings into a painting plant, the SFB determines its position via sensors and calculates the optimum steering geometry for the specific driving task. The exact positioning is then fully automated.

We know the best solution.

We know that handling heavy loads in the aviation industry presents users with special challenges. Arrange a non-binding consultation appointment with our specialists to obtain the best possible solution for your application.