Automation with AGVs & AMRs from HUBTEX

Intelligent intralogistics for long, heavy and bulky loads

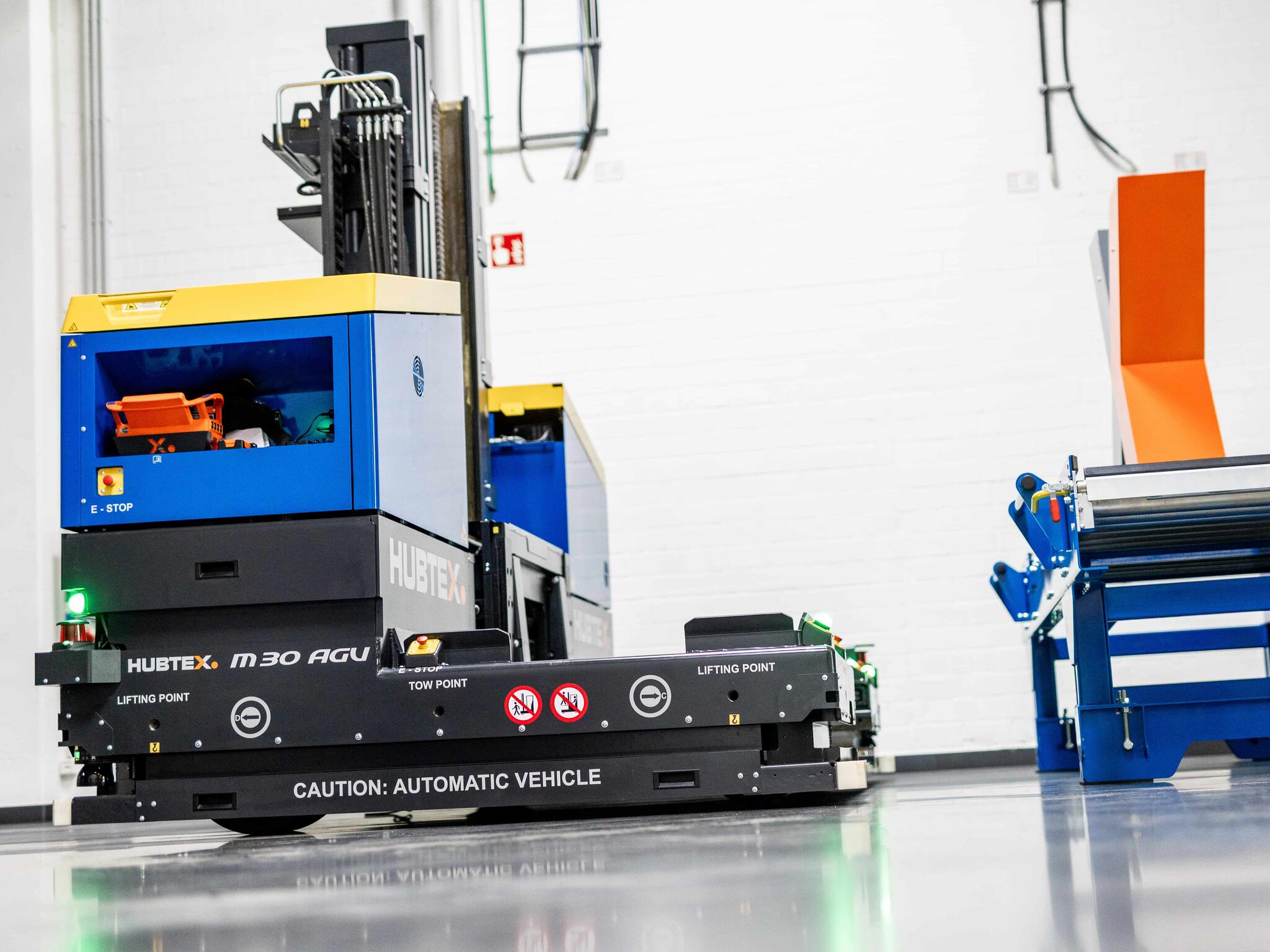

The automated handling of long, heavy and bulky loads is among the most challenging tasks in intralogistics. In addition to traditional automated guided vehicle systems (AGVs), autonomous mobile robots (AMR) are gaining traction, offering enhanced flexibility and scalability in dynamic environments. HUBTEX is renowned for its expertise in automated solutions for heavy and bulky loads. Comprehensive consulting is the focus: Together with our clients, we craft customised automation solutions tailored precisely to their specific needs. By combining cutting-edge sensor systems, intelligent control systems and modular vehicle platforms, we deliver holistic solutions that are seamlessly integrated into existing processes.

Are you interested in learning more about automation at HUBTEX?

Discover how and when automated guided vehicle systems (AGVs) can optimise goods transport for long, heavy and bulky items in this HUBTEX white paper. Gain a quick overview of technologies and methodologies involved in the project.

Effective AGV solutions for moving long goods, glass racks and heavy items

using our automated multidirectional forklifts and specialised vehicles

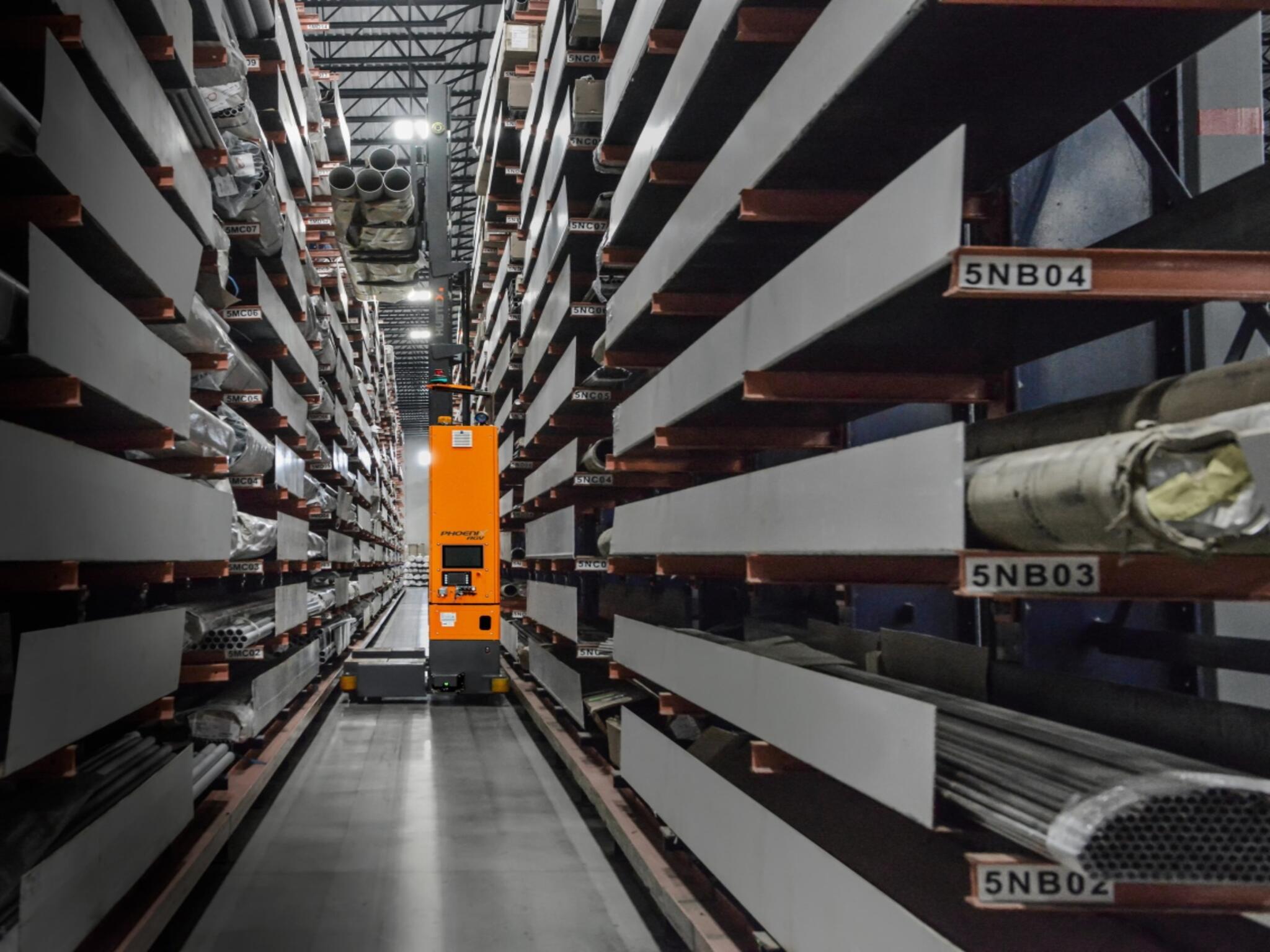

With our automated electric multidirectional sideloaders, the Phoenix AGV series specialises in the transport of long goods either in carriers or specified loads. Typical applications include the handling of profiles or steel.

Our GTR-AGV glass rack transporters are also often automated. In scenarios featuring conditions and sequences conducive to AGVs, these vehicles can serve as alternatives to manually operated equipment.

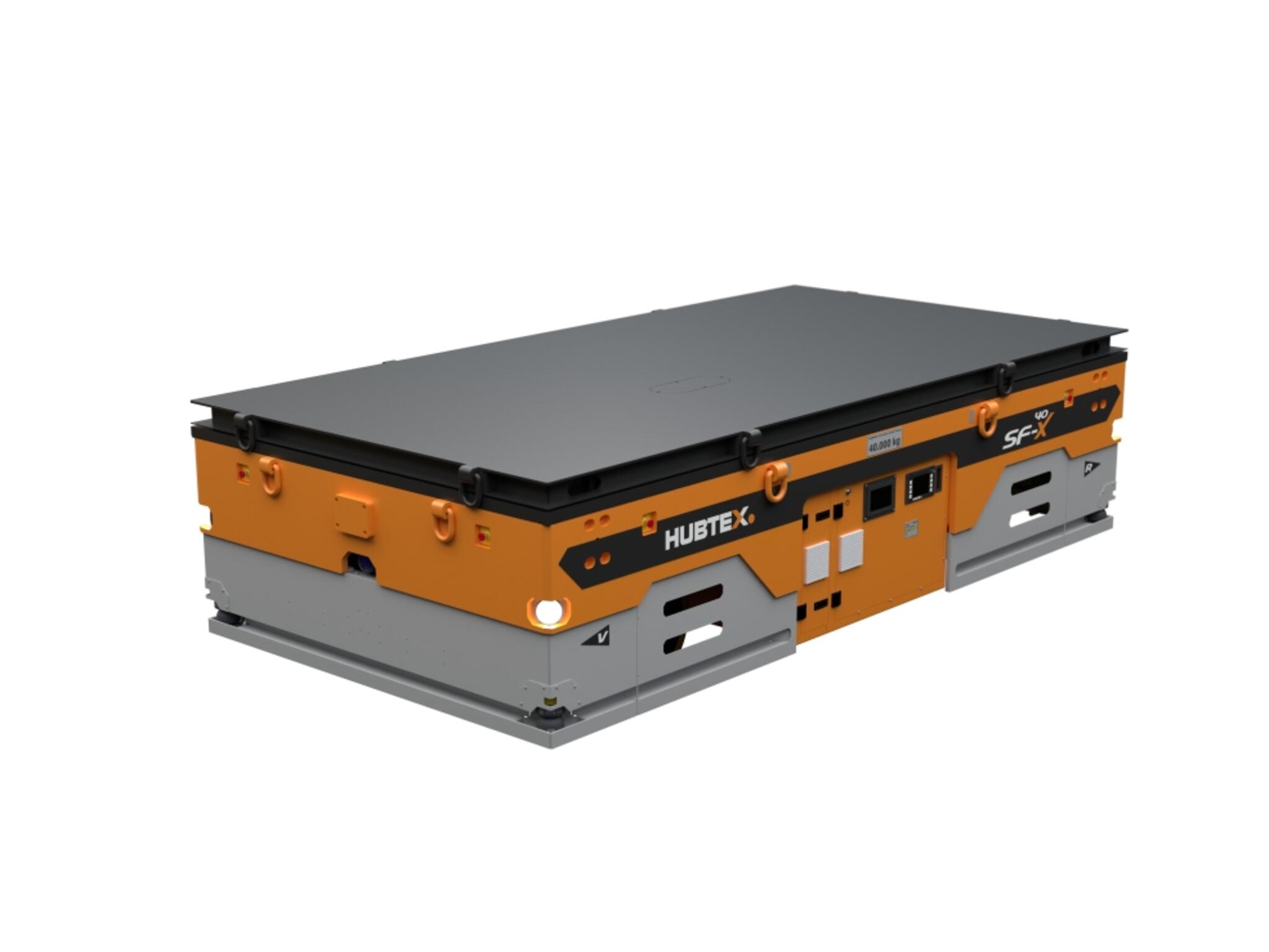

Our heavy-duty platform transporters enable seamless automation of straightforward internal transport tasks . The SFX concept is already prepared for automation and can often be easily and cost-effectively integrated into operational processes.

Advanced technologies meet customised vehicle construction

HUBTEX combines state-of-the-art technologies for efficient and safe automation

Personalised vehicle concepts from HUBTEX enable tailor-made, automated solutions for long, heavy loads – perfectly adapted to your individual requirements and operating conditions.

State-of-the-art technologies like object-based laser navigation ensure reliable, safe and flexible navigation – even in complex warehouse environments.

Unparalleled safety thanks to intelligent systems: Our vehicles detect obstacles, protect people and machines, and meet the highest safety standards for automated operation.

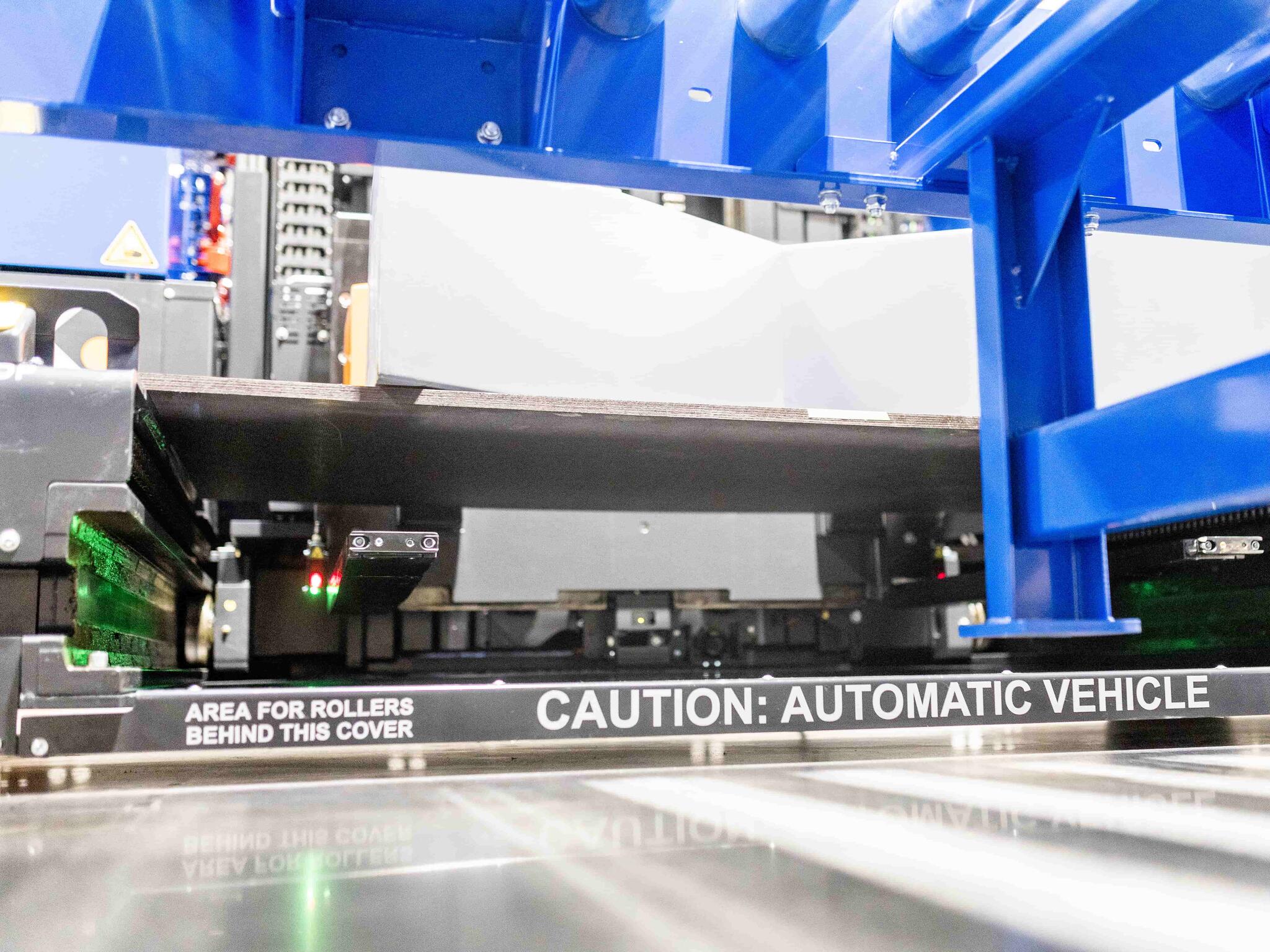

Patented long goods detection along with advanced sensor technology ensure precise load detection, facilitating smooth and efficient material flow without manual intervention.

Our powerful control systems coordinate the entire vehicle fleet, optimise routes, avoid collisions and seamlessly integrate AGVs into your IT and inventory management systems.

Efficient battery management maximises operating times – from energy monitoring to automated charging strategies for uninterrupted multi-shift operation.

Automation in long goods handling

Opportunities and challenges

The goal of modern intralogistics is to maintain high delivery performance, despite the shortage of skilled workers and increasing demands on quality and speed. Automated solutions like AGVs and AMRs are vital for enhancing efficiency, productivity and safety.

Automation, particularly in long goods handling, presents unique challenges. There are only a few fully automated transport vehicles that can flexibly adapt their safety functions and driving kinematics to different loads and their dimensions. One major challenge is accurately identifying the centre of gravity in long and irregularly shaped loads to handle and move them securely. HUBTEX successfully provides customised and phased automation solutions tailored to specific client needs.

HUBTEX modernises a 30-year-old transport system with a customised AGV

for Boeing

Key challenges in introducing AGVs and AMRs

To fully leverage the potential of these systems, several key requirements must be considered:

- Adaptation of processes: Customer processes should be tailored to support the AGVs' maximum performance, while allowing the vehicles to adapt flexibly to individual requirements.

- Ground conditions and operating conditions: The infrastructure must be suitable for automated vehicles – bumps, gradients and other obstacles can affect operations.

- Transfer stations: A seamless transition to and from the automated process is crucial to maintaining efficient material flow.

- Integration into the control system: A robust interface connection provides seamless integration of the AGVs into the existing warehouse and process management systems.

- Optimisation of the routes: The dimensions of the travel routes must be adapted to the protective fields of the AGVs to ensure safe and efficient movement during operation.

HUBTEX supports customers in the analysis, planning and implementation of automation projects – from process recording and vehicle configuration to integration into the control system. This results in bespoke solutions that combine efficiency gains with future security.

Your AGV check – a quick and structured evaluation

Do you want to know whether your automation project can be implemented with HUBTEX AGVs and, if so, how? Our AGV check can help you make a swift and informed decision. We use structured analyses and checklists to capture your requirements and provide a preliminary assessment of feasibility, effort and budget.

Your questions – our answers

about our automated multidirectional forklifts, platform trucks and special equipment

For which applications are HUBTEX AGVs particularly well suited?

AGVs are ideal for repetitive transport tasks in materials handling, especially over long distances. HUBTEX specialises in the transport of long and heavy loads. In long goods handling in particular, the wide variety and changing dimensions of the loads pose a special challenge, which makes automation and the necessary sensor technology more complex. AGV applications are particularly interesting where regularly recurring loads and defined load carriers are used. Thanks to their flexible adaptability, AGVs can be seamlessly integrated into both new buildings and existing premises.

What is the difference between AGVs and AMRs – and which system is better suited to my application?

AGVs (Automated Guided Vehicles) move along fixed routes, often using lines, magnets or lasers, and require a structured environment. AMRs (Autonomous Mobile Robots) are more flexible, can adapt dynamically to environments and navigate around obstacles independently. AGVs are ideal for predictable processes with clear transport routes, while AMRs are suitable for more complex, changing environments. The choice depends on the workflows, infrastructure, and automation requirements – HUBTEX offers both variants and supports you in choosing the most suitable solution.

What is the typical workflow for an AGV project, from planning to set-up?

An AGV project begins with an analysis of your workflows and a feasibility study. Our goal is to quickly provide you with an assessment of the project’s feasibility and the estimated costs, so that you have a solid foundation for your business case early on. Since automation projects are complex, this is followed by a detailed design phase in which vehicle design, navigation, safety requirements and interfaces are planned, specified and calculated.

Once the order has been placed, we start with a kick-off meeting to define the project team, roles and workflows. This is followed by the Preliminary Design Review (PDR), during which the key project points are confirmed. The Final Design Review (FDR) approves the design for production. After manufacturing, the Factory Acceptance Test (FAT) checks that everything functions as specified.

After delivery, installation and commissioning take place at the client's site. Once the system has been successfully integrated into live operation, the client carries out acceptance testing. The final phase is supported implementation during live production, during which the system is optimised under real conditions and any final adjustments are made. The final acceptance and comprehensive training complete the project. HUBTEX remains at your side as your partner with service, support and maintenance.

What requirements must my infrastructure and processes meet for the successful implementation of an AGV?

The successful use of AGVs requires stable, sufficiently load-bearing floors and level, suitable travel routes. There should be sufficient space for turning and safety areas; in larger facilities, a traffic management system may be useful. The travel routes must be wide enough and clearly defined to take into account the safety areas of the vehicles. Ideally, manual and automated processes should be clearly separated from each other. Transfer stations should be stable, precisely positioned and designed for automation to ensure a smooth transfer of goods. They are crucial for facilitating the transfer of long loads in particular.

In addition, internal processes should be standardised and prepared for automation, and connection to ERP or warehouse management systems is also crucial. HUBTEX supports you in analysing your initial situation, checks the conditions on site and develops tailor-made optimisation proposals – for the efficient and safe integration of your AGV solution.

Wie lange dauert ein Projekt AGV-Systems? Welche Zeiträume muss ich für Planung, Umsetzung und Inbetriebnahme einplanen?

Die Implementierungsdauer hängt vom Umfang des Projekts ab. Für kleinere Standardlösungen können zwischen vier und sechs Monaten eingeplant werden, während komplexere, kundenspezifische Systeme zwölf bis achtzehn Monate benötigen können. Diese Zeit umfasst Analyse, Konzeptentwicklung, Produktion, Softwareintegration, Testphasen und die Inbetriebnahme. Besonders wichtig ist eine gute Abstimmung in der Planungsphase, um Verzögerungen zu vermeiden. HUBTEX arbeitet mit klaren Projektplänen und Meilensteinen, um einen reibungslosen und transparenten Ablauf zu gewährleisten.

Wie wird die Sicherheit von Personen und anderen Fahrzeugen im AGV-Betrieb gewährleistet?

AGVs von HUBTEX sind mit modernsten Sicherheitstechnologien ausgestattet, darunter Laserscanner, Not-Aus-Systeme, akustische Warnsignale und visuelle Anzeigen. Sie erkennen Hindernisse frühzeitig und passen ihre Geschwindigkeit oder Route automatisch an. Die Systeme erfüllen aktuelle Normen und Sicherheitsstandards, wie etwa EN ISO 3691-4. Zudem werden alle Sicherheitsfunktionen individuell auf Ihre Betriebsumgebung abgestimmt. Durch regelmäßige Wartung, Software-Updates und Schulungen stellen wir sicher, dass der Betrieb jederzeit sicher bleibt.

Wie wird die Energieversorgung gelöst? Welche Lade- und Batteriekonzepte kommen zum Einsatz?

Die Auswahl des passenden Energiesystems für ein AGV hängt entscheidend von den Einsatzbedingungen ab. In den meisten Projekten empfiehlt HUBTEX eine Kombination aus Lithium-Ionen-Batterien und einem Ladesystem über Ladekontakte für hohe Autonomie. Ein Schlüsselfaktor ist dabei die verfügbare Ladezeit: Fahrzeuge mit kleineren Batterien müssen häufiger, aber kürzer laden, während größere Batterien seltener, dafür länger an der Ladestation stehen. Die insgesamt benötigte Energiemenge bleibt gleich – größere Batterien sind jedoch deutlich teurer.

HUBTEX setzt bevorzugt auf folgende Ladesysteme:

- Ladekontakte: Energieübertragung über Metallplatten oder -stifte mit hohem Wirkungsgrad, niedrigen Kosten und kurzen Ladezeiten. Ideal für saubere Umgebungen wie Lagerhäuser mit planbaren Ladepausen.

- Induktives Laden: Kontaktlose Energieübertragung über elektromagnetische Felder. Vorteile sind kein mechanischer Verschleiß und oft geringere Installationskosten. Nachteile: etwas geringerer Wirkungsgrad (~85–90 %) und höhere Betriebskosten bei begrenzter Ladeleistung.

- Batteriewechselkonzept: Für große Flotten kann ein automatisches Batteriewechselsystem die optimale Lösung sein. Hier werden entladene Batterien automatisch gegen volle getauscht – ideal bei sehr kurzen Ladefenstern und maximaler Verfügbarkeit.

Wie stellt HUBTEX sicher, dass AGV-Systeme dauerhaft einsatzbereit bleiben, und wie aufwendig ist ihre Wartung?

HUBTEX-AGVs sind so konzipiert, dass sie zuverlässig, effizient und mit möglichst geringem Wartungsaufwand betrieben werden können. Jedes Fahrzeug verfügt über einen detaillierten Wartungs- und Serviceplan sowie integrierte Diagnose- und Überwachungssysteme, die frühzeitig auf Störungen oder Wartungsbedarf hinweisen. Regelmäßige Inspektionen sind essenziell. Ein erfahrenes Service-Team übernimmt sowohl die Wartung vor Ort als auch Ferndiagnosen und Remote-Support. Viele Probleme lassen sich dabei bereits per Fernzugriff lösen, ohne dass ein Techniker anreisen muss.

Auch der regelmäßige Check durch den Betreiber, z. B. das Reinigen der Sensoren, trägt zur Verfügbarkeit bei. Zusätzlich bietet HUBTEX Software-Support und technische Schulungen an, um die Kunden auch langfristig handlungsfähig zu machen. Durch diese umfassende Betreuung und das vorausschauende Servicekonzept wird sichergestellt, dass HUBTEX-AGVs jederzeit einsatzbereit bleiben und sich ihre Investition nachhaltig auszahlt.