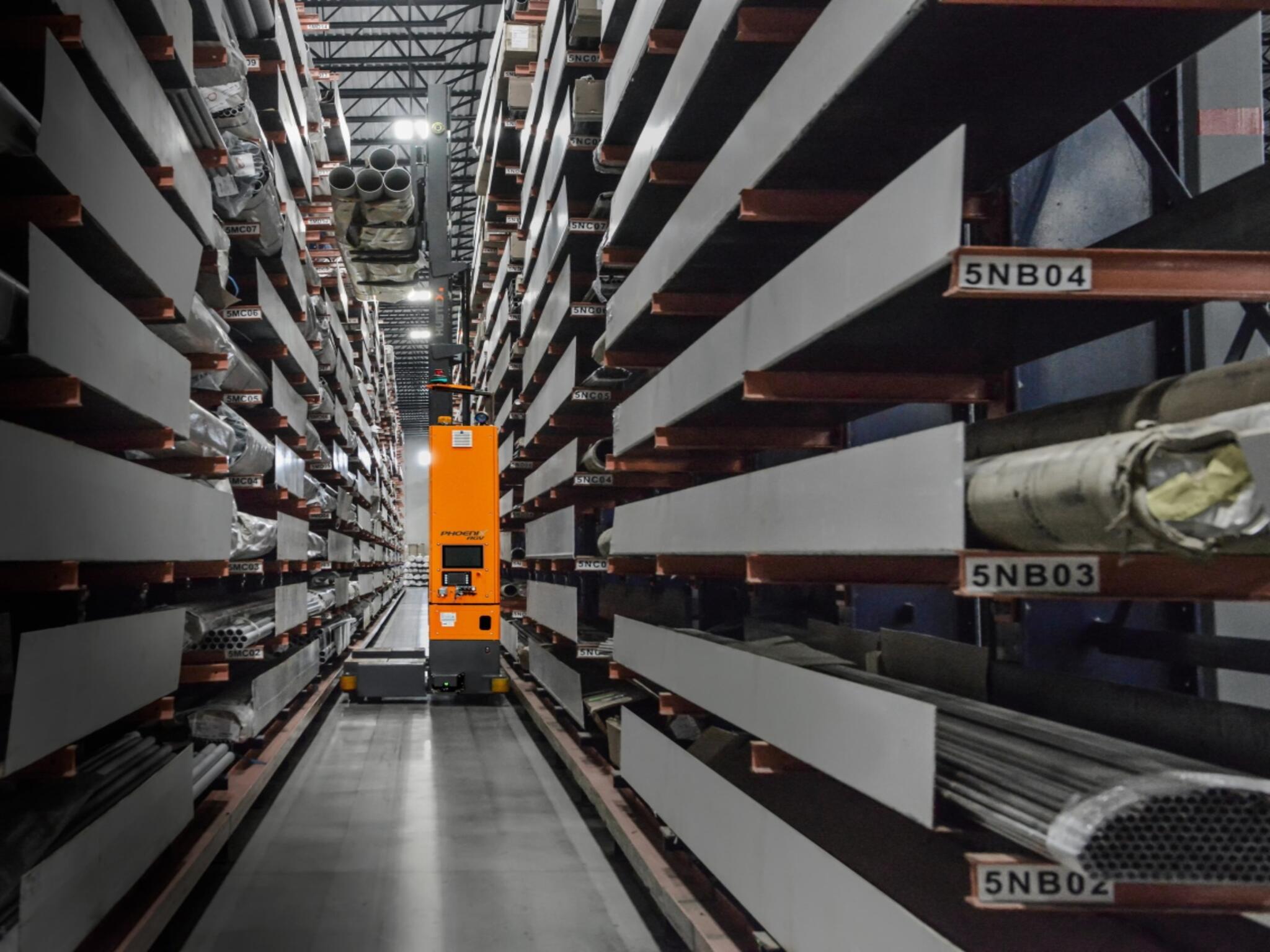

AGVs from HUBTEX

Technological expertise for automated material flow

For the reliable transport of long and heavy loads in automated processes, HUBTEX relies on specially developed technologies. Our AGV trucks are based on robust platforms with integrated components providing sensors, actuators and controls – optimised for driverless operation. Depending on the application, object-based laser systems, transponders or GPS-supported outdoor solutions are used for navigation. Safety features such as 360° personal protection scanners, speed monitoring and safety guidance meet the highest requirements in accordance with ISO 3691-4. Precise load detection is achieved using 3D cameras, laser sensors and smart algorithms for automatic load measurement and identification. The system is complemented by intelligent fleet management with a VDA 5050 interface and active battery management for maximum availability.

A technological focus

Modular in design, precise in implementation, and designed for the highest requirements: Our AGV systems are technologically sophisticated solutions for automated material flow.:

- Truck platform with AGV-specific design

- Various navigation methods

- Safety systems with 360° scanner

- Intelligent load and carrier detection

- Fleet control including VDA 5050

- Dynamic battery management

Based on our many years of experience in special vehicle construction, we offer tailor-made solutions for complex transport tasks in industry and logistics.

Vehicle structure:

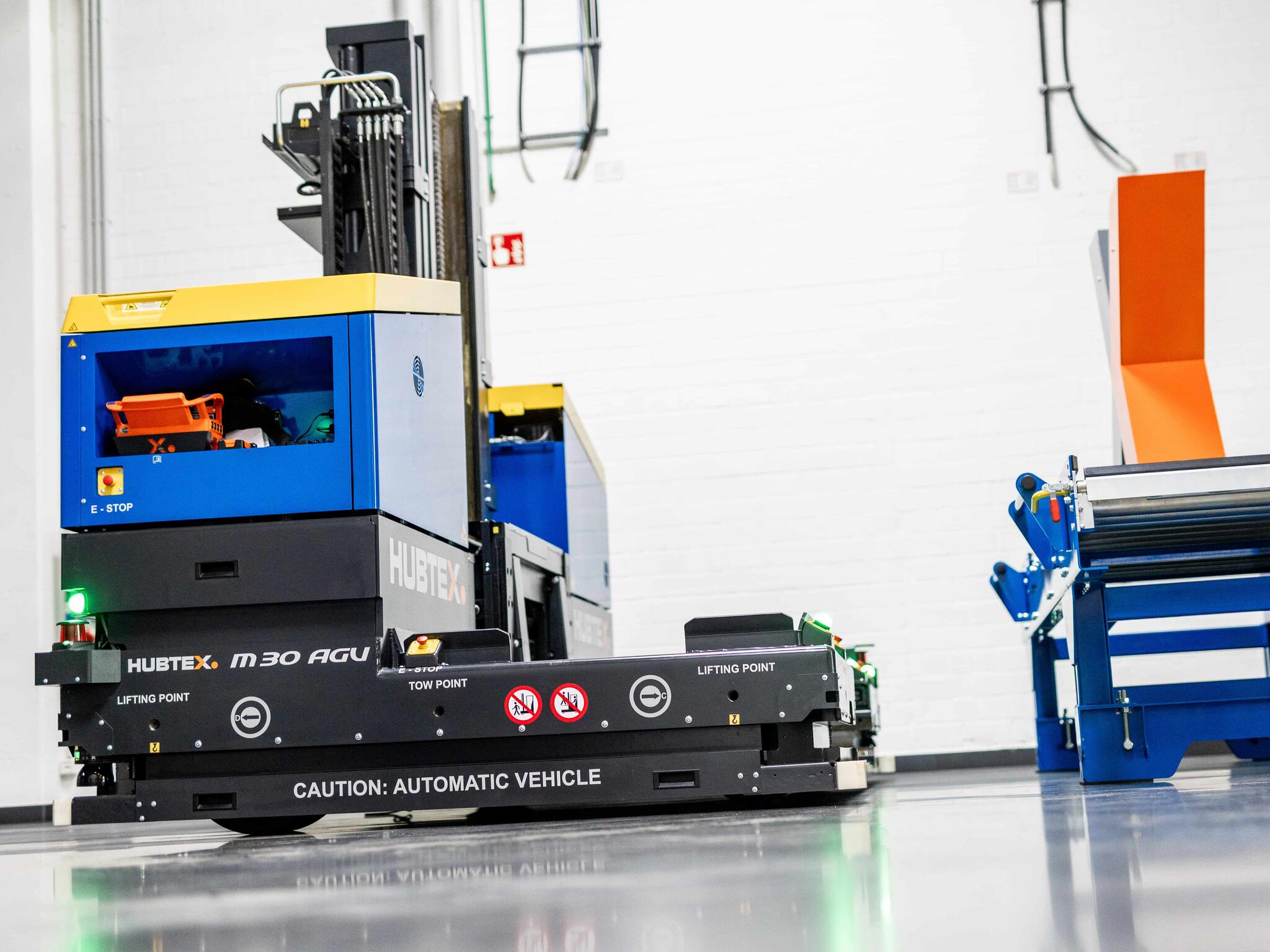

tailor-made solutions for your requirements

The HUBTEX AGVs are based on individual vehicle platforms specifically designed for the automated transport of long and heavy loads. All necessary installation spaces for sensors, actuators and control components are planned during the design phase. This means that the structure is prepared for future driverless operation from the outset. Standard control components are replaced by AGV-specific components.

Typical features

of HUBTEX AGVs include:

- Robust frame in a closed U-shaped design without a driver's cabin

- Laser-based personal protection system for 360° all-round protection

- Additional sensors for machine protection

- Fork carriage with sideshift and optional sensors for load detection and identification

- Popular: PU tyres

- Safety steering electronics with validated functions in accordance with ISO 3691

- Large control cabinet for AGV components

- Robust frame with a closed U-shaped design

- Radio remote control for commissioning and service

- Safe lift height detection

- Emergency stop button, acoustic warning signal, LED status bar and Blue-Spot

- Interfaces to leading navigation systems (Navitec, Kollmorgen)

Special design: In exceptional cases, a HUBTEX AGV can be equipped with a full driver's cabin – for example, if only a few vehicles are used and a backup concept is required in the event of a breakdown, or if infrequent processes are to be automated. However, HUBTEX generally does not recommend a hybrid operating concept (AGV + manual) and also advises against converting manual vehicles to AGVs, as the basic structure is usually significantly different.

In addition to 2D lidar navigation, HUBTEX also offers alternative navigation solutions:

- Wire guidance: cost-effective, proven and easy to control; however, it can be inflexible and difficult to expand.

- Transponder navigation: enables indoor and outdoor use and flexibility within a defined grid, but requires ground preparation and limits ground clearance.

New: outdoor navigation

Since 2023, HUBTEX has been offering an innovative AGV navigation system for outdoor use. The system works by combining different sensor data (e.g. 2D/3D laser, IMU, GPS, radar) and ensures reliable 3D navigation in all weather conditions.

This enables HUBTEX to offer customised navigation technologies for a wide range of applications – precisely tailored to the individual requirements of each project.

Safety:

maximum safety for people, machines and materials

At HUBTEX, safety is our top priority. Our AGVs feature cutting-edge safety technology to ensure reliable, efficient and, most importantly, safe automated operation.

Personal protection scanners and protective fields

The core element of the safety system is the personal protection scanners, mounted diagonally at the front and rear of the vehicle. These scanners detect obstacles all around and dynamically adjust the AGV's behaviour:

- If an object is identified in the warning field, the vehicle automatically reduces its speed.

- If an object is detected in the protective field, the AGV stops immediately and emits visual and acoustic warning signals before proceeding.

- An automatic restart without manual confirmation is possible.

Thanks to adjustable warning and protective fields, our vehicles can reach speeds of up to 2 m/s, even in narrow aisles – this is where safety scanners with particularly large protective areas can be beneficial. The predictive warning field allows for gentle braking, thereby protecting the transported goods. Additional scanners mounted on the mast protect against collisions, while side-mounted scanners detect obstacles to the front and side such as outstretched arms.

Your AGV check – a quick and structured evaluation

Do you want to know whether your automation project can be implemented with HUBTEX AGVs and, if so, how? Our AGV check can help you make a swift and informed decision. We use structured analyses and checklists to capture your requirements and provide a preliminary assessment of feasibility, effort and budget.

An overview of technical safety equipment

- Safety circuit in accordance with VDE 0113

- Safety control

- 360° personal protection scanner on the vehicle frame

- Speed- and direction-dependent protective field adjustment

- Emergency stop button with lock on the chassis

- LED status light and acoustic warning signal

- Blue-Spot warning light in the direction of travel

Safety concept beyond the capabilities of modern technology:

Standards, organisation and operational environment

A safe AGV system relies not only on modern vehicle technology but also on organisational measures and clearly defined operating conditions. Regular maintenance, inspections and training of operating personnel are crucial to minimising risks and ensuring the systems' long-term functional reliability.

Moreover, our vehicles comply with all relevant safety standards – especially EN ISO 3691-4 for automated guided vehicle systems – thus providing maximum legal security and investment protection.

For particularly secure and efficient operation, HUBTEX AGVs are primarily used in enclosed areas. These physically demarcated zones, such as factories, warehouses, airports or hospitals, are separated from pedestrian traffic to facilitate uninterrupted, autonomous navigation. Demarcation is usually accomplished with fences, gates or barriers to prevent unauthorised access and avoid collisions. In these settings, the focus is on access control while keeping the operational area free from personnel. This ensures maximum process security and operational continuity.

Load and carrier detection

Precision for secure material flow

With HUBTEX AGVs, there is a distinction between load detection (identifying the load) and load identification (allocation and comparison with transport orders). Detection can be performed either directly on the vehicle or at the transfer stations.

Maximum process reliability thanks to smart sensors and patented load detection

For reliable and safe operation of our automated guided vehicle systems, we rely on a highly developed combination of sensors and intelligent object detection. For standardised loads with fixed dimensions, safety sensors automatically detect the load and dynamically adjust the protective fields.

Things become more complex with variable or asymmetrical loads: State-of-the-art 3D cameras and 3D laser scanners are deployed to measure the exact length, width, position and any potential misalignment of the load. The determined correction values are transmitted in real time to the navigation system and are immediately taken into account.

Our patented long goods detection and a variety of smart sensors enable precise, automatic load handling without any manual intervention. This reduces potential errors, speeds up the process and increases reliability in complex material flows.

AGV load detection at HUBTEX

Functions and requirements

Reliable load detection is essential for the efficient and safe operation of automated guided vehicle systems (AGVs). Typical functions include barcode capture to verify the transport orders and the detection of free spaces, allowing the forks to accurately pick up the load. In addition, the system determines both the load length and the full length of the transported goods.

For the identification of load carriers, QR codes are employed. If the system detects a misalignment of the load, corrective positioning is automatically carried out. For dependable long goods detection, we employ two redundant sensors on the lift mast. Additional sensors ensure secure positioning and safety of the load during transport.

For AGVs to operate without disruption, both load aids and transported goods must comply with specific requirements:

- Sensors must have a clear view of the load, unobstructed by packaging film or snow for example.

- Ideally, standardised load aids are utilised to minimise variation among different loads.

- Fork access must remain unobstructed; particularly in block storage, entry dimensions must not be too tight.

- The load centre should ideally be as central as possible (± 50 mm).

- Transported goods need to be adequately secured to prevent slippage during an emergency stop (up to 3 m/s² deceleration).

- Pallet detection is carried out directly via the load detector on the back of the fork; additional sensors are not required.

Control system and fleet management

Efficiency and control for your AGV fleet

The control system for HUBTEX AGVs coordinates the entire fleet, optimises routes, manages loading processes, prevents collisions and seamlessly integrates the AGVs into existing IT and inventory management systems. The result is maximum efficiency, reduced costs and increased safety.

Core tasks of the control system in AGV fleet management

AGV fleet management monitors and controls automated guided vehicle systems in industrial and logistics environments. Core tasks include fleet monitoring, where each vehicle's location, operating status, battery charge level and potential error messages are continuously recorded, ensuring maximum transparency in operations. Another key function is route optimisation. Intelligent algorithms determine the most efficient routes to reduce transport times and avoid unnecessary empty runs.

Battery management ensures that the AGVs' charge levels are monitored consistently and that charging cycles or battery replacements are scheduled in a timely manner, thereby guaranteeing high vehicle availability. In addition, the control system coordinates multiple AGVs. Synchronising their movements allows even complex transport tasks to be completed efficiently and collision-free.

Another area of responsibility is maintenance planning, which coordinates maintenance intervals and service operations to minimise unplanned downtimes. Finally, the control system is responsible for safety and emergency management: It enforces safety protocols and initiates emergency procedures, for example in the event of obstacles, malfunctions or unforeseen events in the AGVs’ operating area.

Functionality

The control system receives transport orders (e.g., from the WMS, via call buttons or through direct input), assigns them to individual AGVs, and reports their completion. It factors in elements such as:

- the location and status of the AGVs (free, occupied, soon available)

- battery capacity for the task

- the fastest available route

- the current traffic situation

The control system also manages routes, transfer stations, charging stations, traffic signals, gates and lifts.

Flexible fleet management solutions for AGVs

Manufacturer-specific or open system

For the efficient use of multiple automated guided vehicles (AGVs), HUBTEX offers various fleet management solutions, individually tailored to the system landscape and customer requirements.

For applications with a uniform navigation system, the fleet management solution of the respective manufacturer is recommended. This solution allows for easy integration with clearly defined interfaces and standardised service concepts, perfect for homogeneous vehicle fleets.

For more complex scenarios employing AGVs from various manufacturers, independent fleet managers can be used. These systems enable comprehensive control of a diverse range of vehicle types and are typically already equipped for the communication standard VDA 5050. HUBTEX utilises both its own and external systems, providing additional benefits, for example in the simulation of material flows and processes.

VDA 5050: The cross-manufacturer standard for AGV fleets

Within modern control systems, the open interface standard VDA 5050 is gaining importance. It enables uniform communication between AGVs and control systems, regardless of vehicle type, manufacturer or navigation system. The aim is to centrally and cohesively manage different automated guided vehicles (AGVs) within a unified system.

Standardisation simplifies the integration of new vehicles, speeds up commissioning and significantly eases later system expansions. HUBTEX is actively engaged in advancing VDA 5050 and is already implementing future-proof solutions compatible with this standard.

An intelligent fleet management system enhances productivity, improves operational safety and reduces costs in the long run. Thanks to many years of experience and a broad knowledge of solutions, HUBTEX selects the most intelligent solution for each application, ranging from single devices to complex AGV fleets, which are managed according to the highest industry standards.

Are you interested in learning more about automation at HUBTEX?

Discover how and when automated guided vehicle systems (AGVs) can optimise goods transport for long, heavy and bulky items in this HUBTEX white paper. Gain a quick overview of technologies and methodologies involved in the project.

Battery management

Efficiency for maximum availability

HUBTEX provides various energy systems for its AGVs and develops tailored solutions for each application. Standard HUBTEX AGVs come with lithium-ion batteries (Li-Ion) designed for continuous operation, regular booster charging or a specific transport profile.

During the project phase, we calculate the energy requirements for the AGVs based on planned workflows and throughput performance – using simulation if necessary. Based on these calculations, we customise both the battery size and the charging concept. When a preset energy consumption level is reached during operation, the HUBTEX control system automatically initiates a booster charge or full charge. The vehicle navigates autonomously to the charging station and automatically connects to it. The state of charge along with other operational data, such as the operating hours counter, are displayed on both the vehicle's HMI interface and the central control system. The location of the charging station is determined during the detailed planning stage.

A significant advantage: Li-ion batteries do not emit gases during charging, eliminating the need for special ventilation requirements. This enables the charging stations to be placed flexibly and decentrally within the facility. The charging contacts are integrated directly into the vehicle, while the docking station is permanently fixed to the floor or wall.

Overview of our charging systems:

- Charging contacts: High efficiency, low costs, short charging times. Ideal for clean environments with scheduled charging breaks.

- Inductive charging: Contactless energy transfer through an electromagnetic field. Advantages: no mechanical wear and often lower installation costs. Disadvantages: slightly lower efficiency (~85–90%) and higher operational costs.

- Battery replacement concept: Automatically swaps empty batteries for fully charged ones – ideal for large fleets and operations with short charging windows.

An intelligent battery management system guarantees maximum uptime, efficient energy monitoring and automated charging strategies – perfect for uninterrupted multi-shift operation.