ENERGY MANAGEMENT

AT HUBTEX

LONG-TERM COST SAVINGS WITH INTELLIGENT SOLUTIONS

Diesel versus electric, lead-acid versus lithium-ion batteries, automated or not: When it comes to adapting the vehicle fleet to individual needs, warehouse logistics specialists are faced with many decisions. Hubtex advises these companies with a comprehensive energy concept that takes into account the interaction of the existing warehouse infrastructure, battery and charging concepts and vehicle equipment, and focuses on the needs of the user.

Cost-consuming electricity: internal transport concepts such as industrial trucks sometimes cause horrendous energy costs.

Energy management as a key to success: how electric forklift trucks save electricity and costs in operation.

Our white paper about energy management.

In the search for potential savings and greater efficiency in everyday operations, many warehouse logistics companies are now turning to electric vehicles - a trend that will continue to take hold in the future in the form of increasing fleet electrification. But the decision for the right type of drive is not quite as clear-cut as that. As one of the leading manufacturers of custom-built industrial trucks, sideloaders and order-picking vehicles, Hubtex is therefore focusing on consulting, i.e. tailor-made energy concepts. The aim of these concepts is to achieve high time and cost savings on the one hand and to use the performance capacities of the machines much more effectively on the other.

CHOOSING THE RIGHT DRIVE

based on the Total Cost of Ownership (TCO)

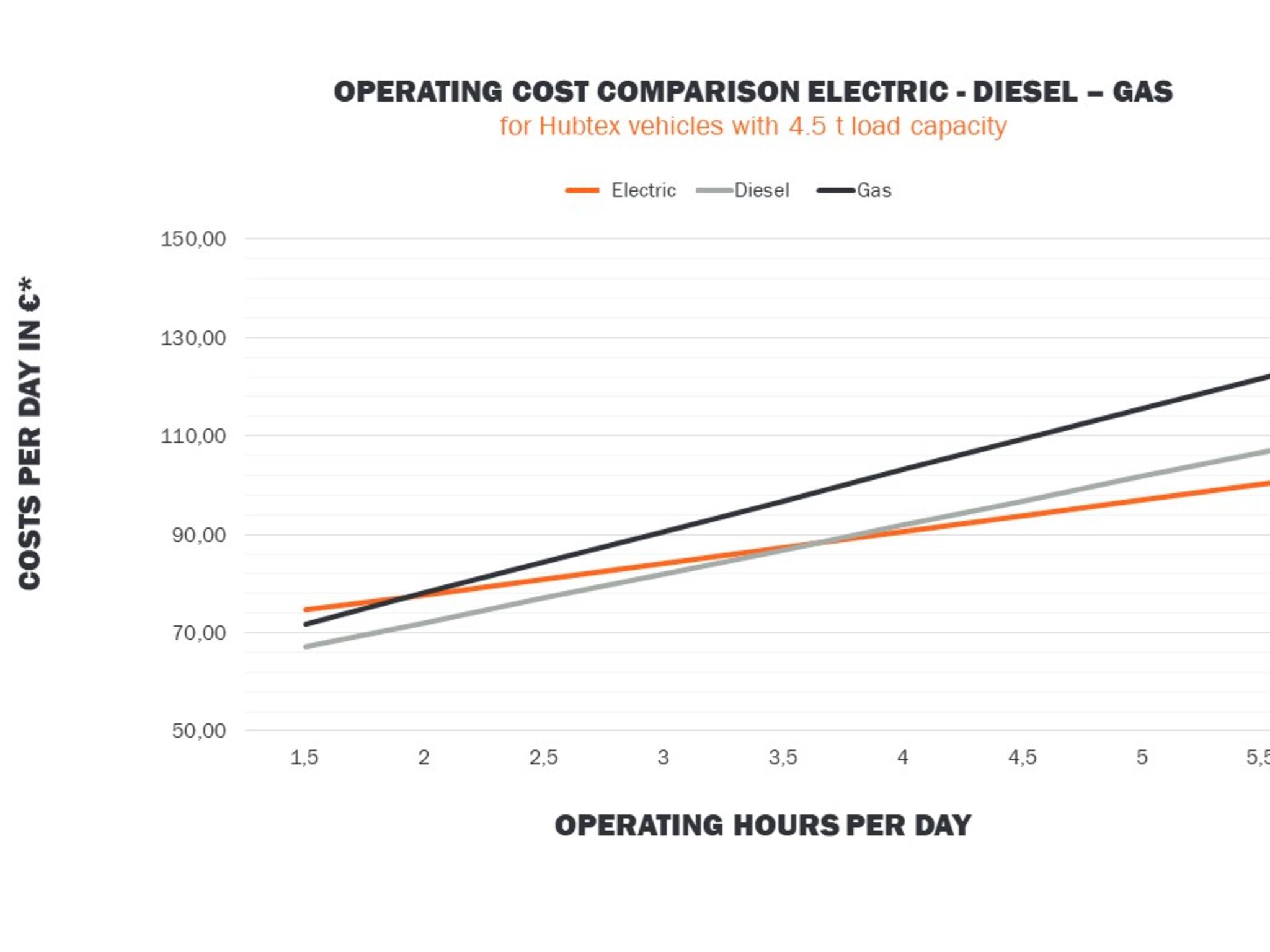

More sustainable management? Many companies are increasingly turning to electrically powered vehicles. However, this decision should also be in line with the actual field of application. Depending on the field of application, performance capacities and application scenarios, the truck with combustion engine may be the better choice. The keyword is Total Cost of Ownership. It is important to note that multi-directional forklifts with combustion engines are generally cheaper to purchase, but the costs for gas or diesel fuel are significantly higher than those for electricity. Electrically operated forklifts are also normally hardly maintenance-prone and require only a few changes of the usual wear parts to achieve the theoretical service life of several years. So if the focus is on active energy management, the choice should be an electric drive with a wide range of options.

Do you have questions about energy management?

We are happy to advise you! Together we will find the best energy solution for your application.

The right battery choice

LEAD ACID VERSUS LITHIUM ION

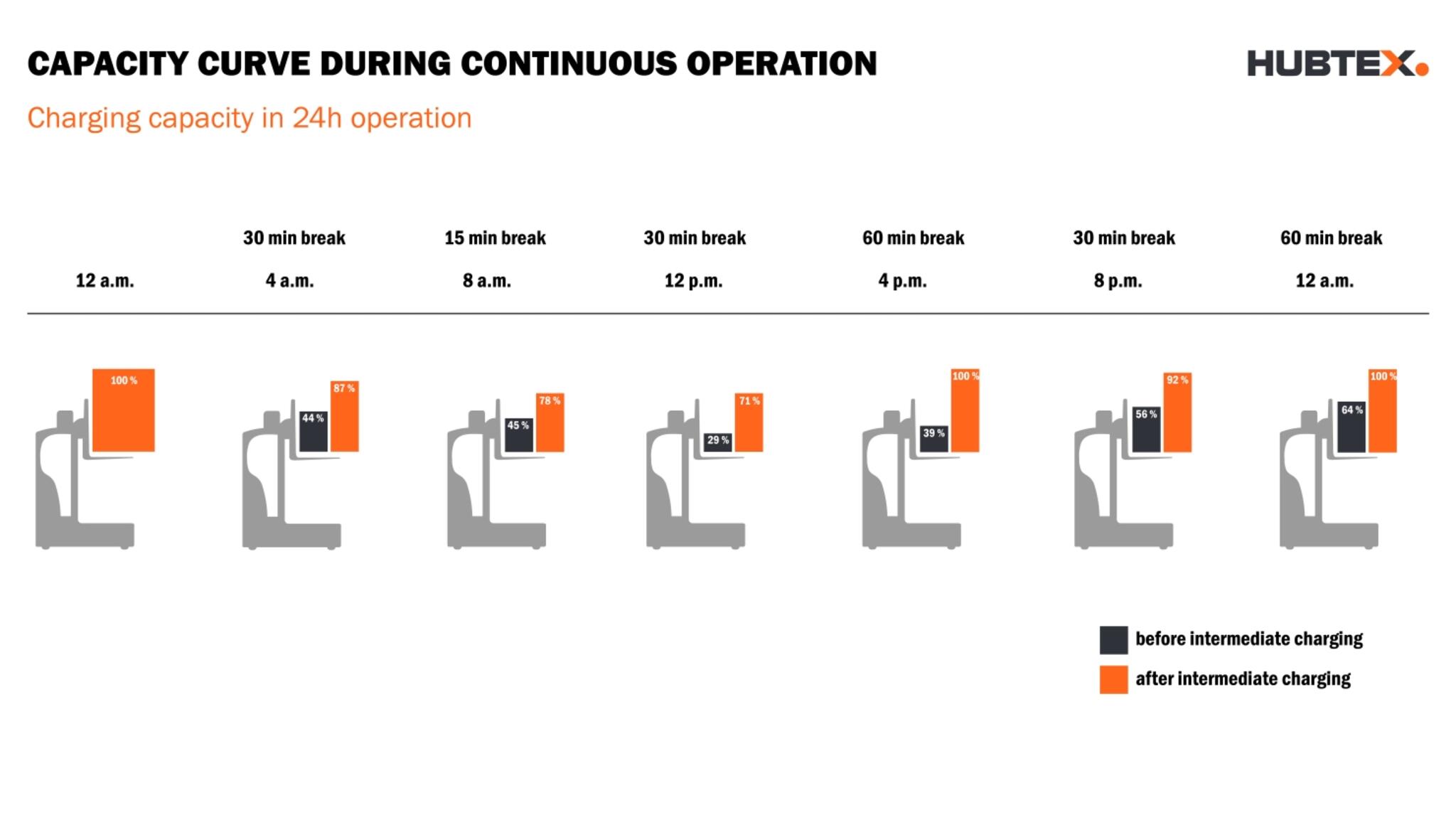

Active energy management therefore works with electric drive. However, this requires batteries. But which ones? Both of the most commonly used technologies have advantages and disadvantages. Classic lead-acid batteries have a charging time of five and a half to fourteen hours, depending on the type of charger, with an average of 1,200 charging cycles and comparatively low investment costs. In multi-shift operations with high operating hours and heavy loads as well as during peak periods such as seasonal business, these batteries reach their capacity limits. The lithium-ion battery, on the other hand, can be fully charged in up to one hour, can be recharged without restriction, is lightweight, can complete up to 6,000 cycles and has a significantly higher energy density than the lead-acid battery. Its use is particularly helpful in continuous operation; for example, the breaks in two or three shifts are used for intermediate charging. However, for less than 1,500 operating hours per year, Hubtex currently recommends the lead-acid battery as the more economical system - even if an exchange battery has to be kept in stock for several shifts. If one compares price and service life, it costs around five to six times less than the lithium-ion battery, but only has a fifth to sixth of its service life. Ultimately, the user should rely on the technology that offers the right performance capacities for the desired application.

HOW TO CHARGE THE BATTERY CORRECTLY

After selecting the battery, the decision for chargers and concepts follows. And the technology is the most important factor here. This determines the system effectiveness of the battery technology. In other words: lead-acid plus HF charger has a much higher efficiency than the combination with a 50 Hertz charger; the combination of lithium-ion plus HF charger is even more energy efficient. If the user chooses the latter, he benefits from lower consumption, but also has to invest more money. A glance at the operating hours reveals whether the extra cost is worth it. Hubtex bases its advice on well-founded comparative calculations. The most economical solution is always a balanced combination of charging technology, battery charging stations, changing concepts and on-site energy infrastructure. The handling of the battery is also an important issue. Battery replacement and maintenance during operation cost a lot of time; in addition, changing devices such as slewing hall cranes or roller tables as well as filling stations must be planned.

ENERGY-EFFICIENTLY EQUIPPED

with the appropriate features

In addition to battery and charging technologies and replacement concepts, the technical vehicle equipment is crucial for energy efficiency. Although a standard electric vehicle has an electric drive, steering and lifting are usually operated hydraulically. In comparison, Hubtex recommends electric steering with low energy consumption. Other equipment options include track guidance systems and personal protection systems, which consume a relatively large amount of energy. Various parameterisations of lifting and travel speeds can also achieve energy savings. It is important to understand the vehicle, battery and charging technology as a complete system and to calculate the expected return on investment in the consultation. The formula applies: Equipment in relation to service life in relation to energy consumption.

CLASSIC OR AUTOMATED?

the costumised solution for your warehouse

Automated Guided Vehicles (AGV) are becoming more and more popular. They are convincing with effective ways and independent processes that relieve warehouse logisticians in everyday operations. But here, too, it is worth taking a second look. An AGV for 24-hour operation with a lithium-ion battery requires contactless charging methods via charging contacts or inductive charging technologies. However, these are very cost-intensive. If this does not pay off, fully automatic vehicles are often used, but the connection to the charging technology is done by an employee. The hydrogen fuel cell also appears to be a drive method with future potential. However, at present it is not as energy-efficient as the electric drive with lithium-ion batteries. Accordingly, only companies with very large fleets should think about such a technology.

The right energy concept for your application

Save costs and conserve resources

This article shows: The topic of energy management must not be ignored in warehouse logistics when using industrial trucks and other transport concepts. Hubtex supports users in the selection of the appropriate technology, i.e. the technology that is suitable for the application, and evaluates energy costs in advance. Ultimately, the aim is to create an energy concept that conserves resources, reduces the costs of ongoing operations and is completely tailored to the user's individual needs.

Individual products for individual challenges

We are happy to advise you! Together we will find the ideal handling solution for your challenge.