AUTOMATED TRANSPORT OF LONG, BULKY AND HEAVY LOADS

Intralogistics is just one of the many sectors struggling with the pressure of digitalisation and the shortage of skilled workers. In view of these internal challenges, it is not getting any easier to meet the various external challenges. These include rising customer expectations of shipping and product quality.

This shows that order picking must become even more efficient and secure. One way to achieve this is through the automation of intralogistics.

The automation of intralogistics is not yet very advanced, especially in the transport of heavy, long and bulky loads. The interest is there, but the question of whether such an investment makes sense is asked again and again.

HOW HIGH IS THE INVESTMENT FOR AUTOMATING INTRALOGISTICS?

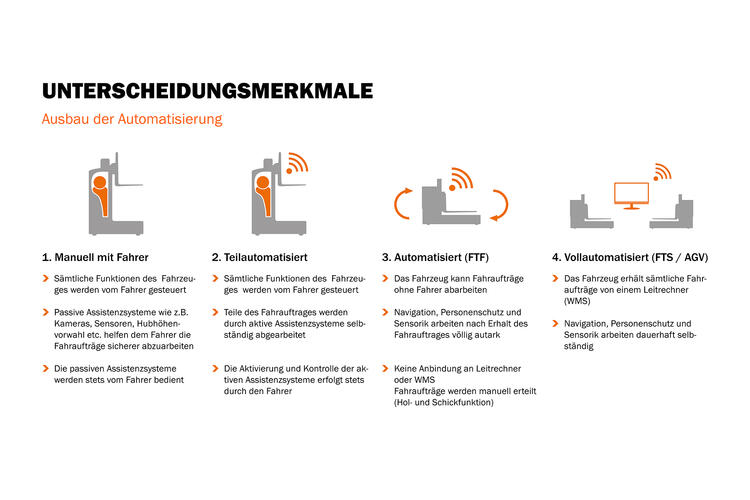

The investment depends entirely on the degree of automation of the solution. The different logistics processes are usually also automated to different degrees. The degree ranges from manual with a driver to a fully automated system. The higher the degree of automation, the higher the initial investment will be. On the other hand, the operating costs decrease as the degree of automation increases and even higher initial investments are amortised after a short time.

Many logisticians prefer traditional automation solutions, such as sorting systems and conveyor systems. However, the space and capital requirements are very high. At the same time, such a fixed infrastructure is not easily scalable, if at all.

Automated Guided Vehicles (AGV) are much more suitable. These vehicles require little to no adaptation of the existing infrastructure. Even the transport of goods through several buildings is possible. If the warehouse layout changes, they adapt themselves automatically. With an AGV, even the automated safe and efficient transport of long, bulky and heavy loads becomes possible.

Whitepaper: Automation and vehicle from a single provider

WHAT MUST AN AGV BE ABLE TO DO?

An AGV must be able to transport goods safely from A to B without supervision. This is made possible by many different safety technologies. Finally, the AGV, such as our PhoeniX AGV, should be able to meet the following requirements:

- Dynamic mapping

- Avoiding obstacles

- Detection of protruding load

- Large lifting heights

- Precise positioning

- Transport of heavy loads

- Load detection

- Block storage

Would you like to learn more about amortisation and other exciting questions? Then download our whitepaper on the topic.